Trains run on big metal rails made out of steel. These rails are simple, tough, and fit for purpose. With no surface treatment, they stand up to the elements and the punishment from hundreds of trains passing by every day. They’ve changed little in recent decades. But then certain railways decided to start painting their tracks – and not just to be fashionable. Let’s examine why.

Today’s railways face a new challenge: excessive heat. As the global warming narrative finally makes good on its dreadful promise, daily temperatures are hitting exceptional highs in some areas. These temperatures often exceed what were once considered reasonable design limits for conventional railways.

The result? The rails expand too far on hot days, and all hell breaks loose. The British call it “buckling.” The Americans, inexplicably, call it “sun kink.” No matter what it’s called, the solution to this problem might be exceptionally simple: white paint.

We've certainly been feeling the heat– but we're not the only ones.

Did you know extreme heat can also affect train tracks?

Check out our blog to learn how: https://t.co/OzsJIAYrjL pic.twitter.com/0FXh7N4wPz

— CapMetro (@CapMetroATX) August 17, 2023

Paint It White

Hot summer days are becoming too much for infrastructure around the globe. Whether you’re dealing with a bridge in New York or a railway in Britain, the root cause of your problems is likely the same: Heat makes metal expand. Engineers account for this when designing infrastructure, but they can only do so much. Eventually, if things get too hot, they expand too far, and you get problems.

As rails grow longer in the heat, they tend to buckle, typically pushing out laterally and breaking free of their sleepers or ties. This can be a great danger, as buckled rails no longer maintain the correct orientation, support, or separation distance to support passing trains. Derailments are common on buckled track if the problem isn’t identified before a train reaches the deformed rails.

Modern railways use continuously welded steel rails, where each length of rail is welded onto the previous one to create a continuous run. In extreme cold, the steel rails may contract so much that they snap, and in extreme heat, they may expand so far that they buckle or kink.

asdf

The temperature range a railway can operate in is set during the construction process through a process called “rail stressing.” The track is installed in a stressed state, such that at a given “stress-free temperature” (SFT) there is no tension or compression caused by thermal effects. In the United Kingdom, for example, rail is typically installed so that it sits in an unstressed state at 80.6 °F (27 °C), the mean temperature in summer. In the US, rail is usually set for a stress-free temperature of 95 to 109 °F.

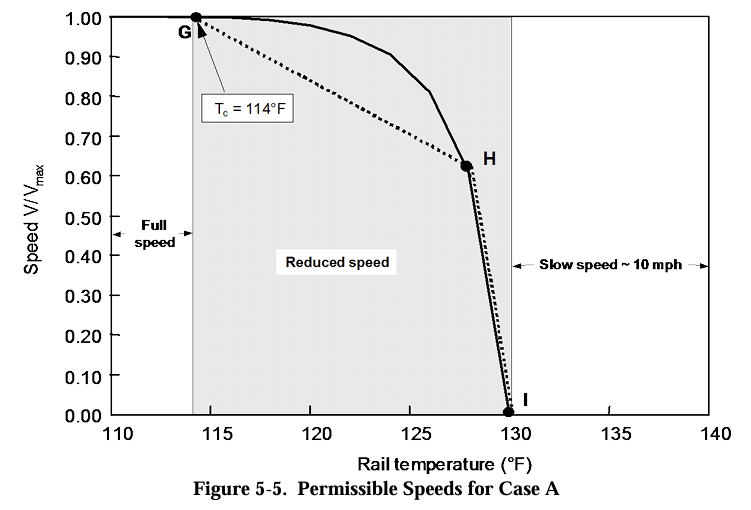

However, exceed this temperature by too much, and the rail may buckle. With an SFT of 80.6 °F, much of the British rail network is safe up to a track temperature of 114 °F (46 °C) before it buckles. This corresponds with an ambient temperature of around 86 °F (30 °C). However, as ambient temperatures continue to rise, rails are at times exceeding 123 °F (51 °C). The hotter the temperature, the more likely the rails will buckle.

Numerous mitigation methods exist to avoid buckling. On hotter days, railways may choose to run trains more slowly, in an effort to reduce forces on the rails and lessen any destabilizing disturbances. Services may be canceled entirely to avoid the risk of derailment.

Rails can also be installed with higher stress-free temperatures, allowing them to withstand hotter conditions. However, this makes them more susceptible to fractures in cooler temperatures. This is often unacceptable for areas with cooler climates.

(5/15)

????️ If we stressed our rails for exceptionally hot weather, they wouldn’t be safe for the winter and we’d have broken rail because it’s too cold. ❄️???? That’s why other countries choose different temperature ranges depending on their climate. pic.twitter.com/VVCLbPT5NB

— Network Rail (@networkrail) July 19, 2022

Cooling the rails is becoming an altogether more popular solution, however. It’s remarkably simple to achieve, too. Simply by covering the rails with white paint, their temperature can be reduced by anywhere from 9-18 °F. In many cases, this is enough to bring the rails back down to a reasonable temperature where buckling isn’t an issue.

Only the sides of the rails are painted. There’d be no value in painting the top, as paint would quickly wear away under the weight of a locomotive. Besides, the shiny top surface is relatively reflective already.

Spotted white rails while looking our your train window? We paint these so they absorb less heat – and expand less. Typically, a rail painted white is 5°C to 10°C cooler than one left unpainted. pic.twitter.com/KRs7Zndkmm

— Network Rail Scotland (@NetworkRailSCOT) July 16, 2022

The mechanism behind this is simple. The dark surface of a railway track will absorb a great deal of heat energy from the sun. Cover the track in white paint, however, and a great deal of that solar energy will instead be reflected rather than absorbed. Having absorbed less energy from the sun, the track will remain cooler. The same technique works for buildings, too, and has been considered a useful technique to help keep homes cooler.

Paint can be applied simply by hand, or with specialist equipment. In Britain, rail workers are stuck trudging along with brush and bucket. Indian railways appear to have developed push carts to do the job more easily. Italian railways use dedicated service vehicles to spray the rails. In certain areas, the paint is applied each summer to keep temperatures in check.

Brits paint by hand.

Indian crews use push carts to spray the rails.

Italian operators have a spray vehicle built especially for this purpose.

Painting the rails might seem odd at first glance. Under normal circumstances, it would seem like a fool’s errand. “Go and paint the rails to keep the sun off!” you’d tell the apprentice. And yet, white paint is instead proving a crucial tool for railways to keep their operations running under hotter summer temperatures. It’s a strange world we live in, but as it changes, we’ll find ourselves turning to strange solutions like these more often than you might think.

Image credits: Network Rail, Network Rail via Facebook screenshot, Ferrovie.info via YouTube, US DOT

That Italian video seems like they are over spraying onto the ground and wasting a lot of paint. After watching them paint the stripes on the road in front of my house, I would expect that with some more modern tech they could paint just the rail and maybe spikes and plates, if needed. Oh, maybe throw some AI at it.

Anyone tell snow piercer about steel stress in cold yet?

Scientists/Engineers: Painting the train tracks on the sides will significantly reduce track temperature and related buckling. Would you like us to design a rail cart to be able to quickly paint all the tracks in the network?

UK: Best we can do is give a guy a mop and bucket of paint.

Sad that the Brits haven’t discovered spray painting yet. Here in the US we have pickup trucks with undercarriage add-ons that let them run on the rails. It would be easy to have a big tank of paint in the truck bed and some nozzles similar to what they use for painting lines on the roadways.

Sounds like a job for Banksy

Once again; just because the British invented trains, it doesn’t mean that we’re any good at them.

I found a good explanation of this phenomenon on reddit

https://www.reddit.com/r/askscience/comments/w2wgez/how_do_train_tracks_withstand_hot_and_cold/

Suddenly all the homophobes are rushing out to slather themselves in white body paint to make sure they stay straight!

We get it, you don’t have a sense of humor. It was only intended to offend homophobes btw.

“With all due respect, you Sir are a fucking moron”…

That’s not how that works. But seriously, why are you so pissed off? Are you a homophobe or just feel like you need to defend that poor oppressed segment of society? Maybe you don’t know what ‘homophobe’ means? I really truly want to understand.

Whoa, what could possibly trigger someone this much in a joke making fun of homophobes? What made you comment once, come back, comment again passing judgment on the couple people who liked the joke, and force engagement to say that you won’t be engaging, ending four paragraphs about how bad it is to insult people with an ad hominem insult?

I hope you get a chance to re-read this whole interaction and understand who’s actually being insultuous here.

It was only meant to offend homophobes

He must be having a bad day. So it was a bad joke. Whoop de doooo.

That’s not paint!!

Let’s be petty and childish. HahI I got FIVE likes!

Is that in the southern US? In the north we rarely hit 95, never mind as an average. Plus, our winter temperatures would result in something like a 110 degree drop from the stress-free temperature, which seems…bad. I would expect northern rails to be something closer to the UK temp.

Keep in mind that this is the temperature of the rail, not the air.

Ah, that does seem more plausible.

In Maine yesterday I got in my car and it read 99 on the outside temp gauge. The official temp for the day was 88, but it was hot out there on the asphalt. Radiant heat does make a difference.

That Indian video has very concise, simple narration paired with some of the most epilepsy inducing editing I’ve seen.

I wonder if the Brits are sticking with manual labor to keep the tracks open while they’re being painted.

You mean ‘labour’…

You ‘avin a laugh?

Quite similar to the experiments with painted or lighter colored pavement, to try to reduce urban heat islands

The thing about pavement is that it regresses to the mean. Asphalt starts out black, concrete starts out white. Within a few years, they’re both gray.

Without reading: because they reflect more heat and won’t warp when they’re not absorbing everything dark steel will.

After reading: hmm yes, smug know-it-all levels are appropriately high.

It does seem like this would be extremely easy to automate. I mean shit, a road is harder to paint correctly (and if the lines near me are any indication, it very much shows). A rail line has two fixed tracks a fixed distance apart. Send a painting cart down the track, top off the paint hopper every once in a while, and validate with pretty much any visible or IR light source for reflectivity. Intervene with a human at missed spots and junctions as appropriate.

That doesn’t offend my sensibilities. A human or two in the loop is a valuable thing, especially when a failure mode includes uncontrolled railway cars (carts? tooling? what’s the word for something less than a car or engine, but not either of those things?).

I mean, yeah, the Italian video in the bottom of the piece demonstrates just that. Quite easy to build a railcar to do it

It seems to me that the way to do this would be with one of the rail trucks.

Get or make something like this, https://www.vezosusa.com/vezos-products/view-all-products/line-striping-machines/truck-mounted-stripers/roadmaster-2-5-line-striping-pickup-truck-detail.html Of course it would need a different spray head system to do both sides of both rails. Then when summer is over pull it out and put it in storage for the winter and use the truck for other purposes.

Deadly dangerous, but also thrilling…in the dullest of repetitive ways. My Bonus Son was a Conductor for a few years and the dullness was what pushed him out of that career. So yeah I do know more than the average bear about the rail system, but of course not that much.

Also to be clear I was just saying the simplest piece of equipment that would do the job in an automated manner and didn’t imply that it would make it a 1 person job. Even if it ended up “needing” a 4 person crew they would still get way more miles done per hour that 4 guys with mops. Heck just give the guys a sprayer with a guide instead of a damn mop.

He went into the Air Force (one of it not the oldest in his group for BMT), became a Crew Chief and got his A&P license. Now that he is out he is working in that industry and making good money. His old boss did contact him several times while he was still in the service and told him that he did have a job as soon as he was out. He did consider it for about 2 sec while he was still looking for his current position.

Yeah, except now we can all tell when they haven’t cleaned the rails in ages.

So in the future is there no way to automate this painting process when they come from the plant? Or is that just not worth it?

They might be able to use an enamel for the factory coat, but it still wouldn’t last the life of the rail.

Looking at the application of the thick white paint, I’m pretty sure they got a bunch of landlords to do those rails.