I have miraculously stumbled upon priceless relics of automotive history: the factory service manuals for the General Motors EV1, the legendary electric car so far ahead of its time that GM had to take every one back from celebrity owners like Mel Gibson and Baywatch actress Alexandra Paul, and crush it. The drama surrounding the destruction of this beloved vehicle — the very first purpose-built, commercially-viable electric car — cannot be understated, with a multi-week vigil attended by numerous celebrities, and a famous film called “Who Killed The Electric Car?” Everyone loved the EV1 because it was incredibly innovative, and there’s no better way to get a glimpse of these revolutionary innovations than to look through these priceless service manuals I now have in my possession. Get ready to have your minds blown.

Some Background On The GM EV1

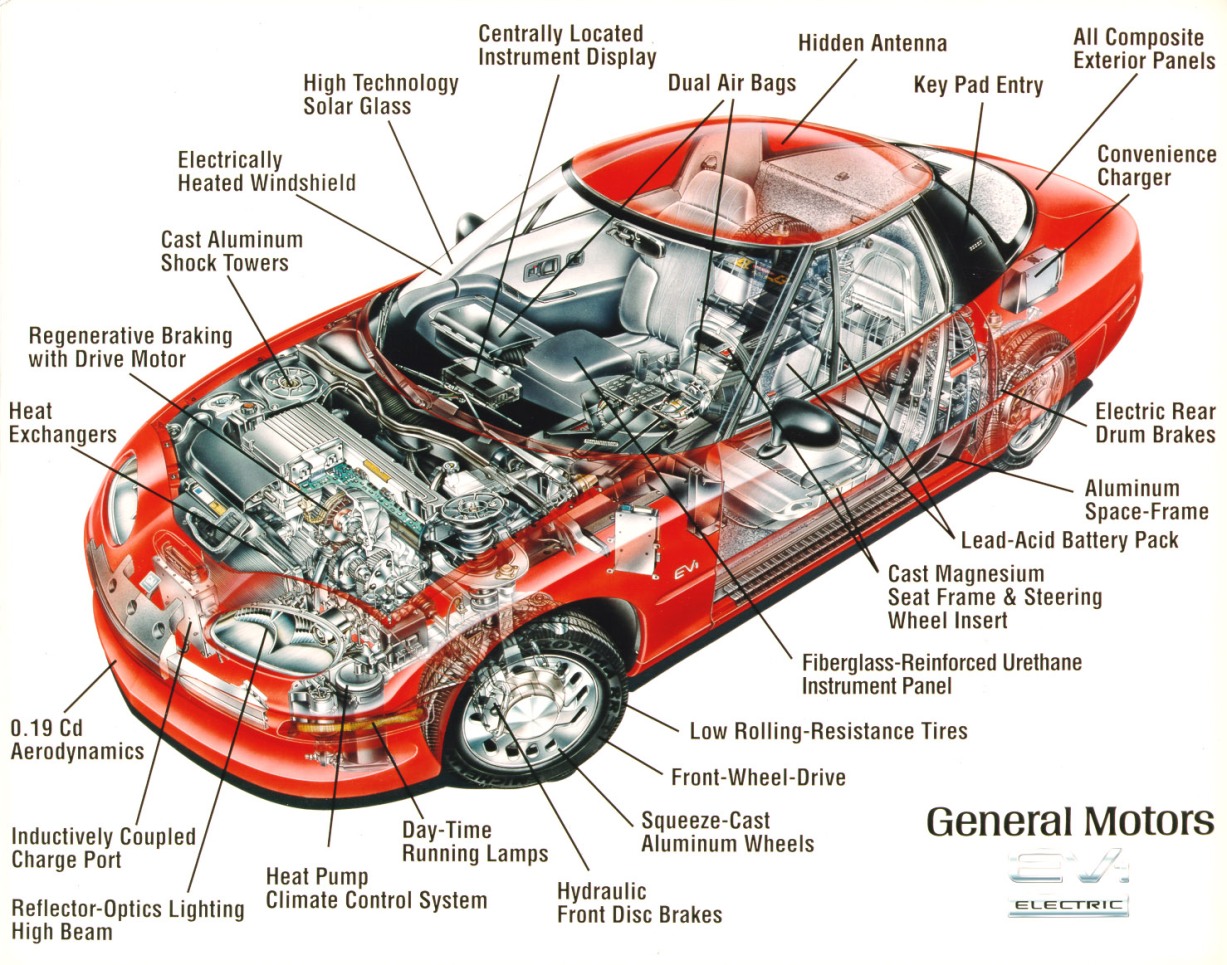

Just to give a little context for those of you not familiar with the EV1: It was an unbelievably advanced electric car built by General motors between 1996 and 1999, and leased to about 1,100 folks, many of whom were celebrities on the west coast. Car and Driver mentions the car’s impressive innovations, many of which are being leveraged to this day in modern EVs (note that some of these aren’t true “firsts,” but all of them were cutting edge):

The list of technologies designed, developed, and put into production by that talented and tireless EV1 engineering force is truly impressive. On the EV1 were many industry firsts and many widely used today in both ICE and EV vehicles. Among the most significant were: power electronics design, packaging, and cooling directly related to today’s EVs; electrohydraulic power steering (EHPS), which soon led to electric power steering; heat pump HVAC (the “grandfather” of today’s systems); low-rolling-resistance tires; inductive charging (now widely used for phones, electric toothbrushes, and other things); an electric-defrost windshield (virtually invisible embedded wiring to defog the glass); keyless ignition (the EV1 used a console keypad); electric brakes and parking brake; by-wire acceleration, braking, and gear selection; cabin temperature preconditioning; tire-pressure sensing; regenerative braking (including variable coast regen—which was on our early development cars but just two set levels selected by a shift lever button on production EV1 cars, due to legal issues with brake-light activation), and regen/friction brake blending; IGBT (replacing MOSFET) power inverter technology, and low-friction bearings, seals, and lubricants.

People loved the EV1, even with its range of only 55 miles or 105 miles (55 with the lead-acid batteries, 105 with NiMH batteries). Back in the 1990s, these were respectable range figures, and the way the car drove — something many people are only now recognizing as they pilot EVs for the first time — was unlike anything most folks had ever driven. The response from that electric motor, the regenerative braking, the silence — it was fantastic.

Look at the graphic above, and you’ll see technologies that were unheard of in the 1990s. The 0.19 drag coefficient still beats that of any Tesla; the cast aluminum strut towers (here’s GM’s patent) were innovative back then, and you could argue might have inspired Tesla’s GigaCastings; low rolling resistance tires were really barely a thing a the time; the heat pump that is so important to modern EVs getting decent range in the winter was super advanced, as well, and wasn’t found in even much more modern electric vehicles like the early Tesla Model 3. Add the aluminum space frame construction, hidden antenna, and optics-headlights and GM had something truly state-of-the-art.

The vehicle was so beloved that, when GM pulled the plug on the egregiously expensive program that, one could argue, was perhaps a bit early given where battery tech was at the time (“I said, ‘Roger, just keep in mind what we have here. We’ve got about a gallon of gasoline worth of energy in those 870 pounds of batteries, and we effectively re- fuel it with a syringe'” is an amazing quote from former president of energy and engine management, Don Runkle, referencing former GM CEO Roger Smith (via Automotive News)), hundreds of people took to the streets. Check out the Washington Post’s 2005 piece, “Fans of GM Electric Car Fight the Crusher,” about a multi-week protest organized after folks noticed EV1s sitting in a lot in Burbank:

Those cars are rarities, the last surviving batch of rechargeable electric coupes built by General Motors Corp. in the late 1990s. Paul and a band of homemakers, people with desk jobs, engineers, Hollywood activists and car enthusiasts are 23 days into a round-the-clock vigil aimed at keeping GM from destroying the cars.

What’s at stake, they say, is no less than the future of automotive technology, a practical solution for driving fast and fun with no direct pollution whatsoever.

The story goes on:

Enthusiasts discovered a stash of about 77 surviving EV1s behind a GM training center in Burbank and last month decided to take a stand. Mobilized through Internet sites and word of mouth, nearly 100 people pledged $24,000 each for a chance to buy the cars from GM. On Feb. 16 the group set up a street-side outpost of folding chairs that they have staffed ever since in rotating shifts, through long nights and torrential rains, trying to draw attention to their cause.

GM refuses to budge, but several factors give those at the vigil hope. The auto industry underestimated the appeal of gas-electric hybrid vehicles, and now the Toyota Prius, Honda Accord Hybrid and Ford Escape Hybrid are selling faster than factories can build them.

Incredibly, despite all of its innovations, the EV1 program was shut down, and GM used very little of the learnings, allowing the Toyota Prius to become the “it” car for environmentalists, selling in absurd quantities and bringing huge wealth and market penetration to Toyota. In typical GM fashion, it was “Hurry up and wait,” and by “wait,” I mean “let everyone catch up.”

This incredible feat or innovation and admiration ended up becoming a PR nightmare for GM, as this San Jose St. University article describes:

When the development cost was averaged among those cars their cost was about $340,000 each. That average cost is not the relevant figure. Of more relevance is what General Motors calls the piece cost, which economists call the marginal cost. That cost seems to have been somewhere in the range of $16,000 to $18,000 in 1992. That would be about $25,000 to $28,000 in 2012 prices. About one half of the piece cost came from the propulsion system. The piece cost does not include the cost of equipment and structures and other costs associated with the enterprise. One can get an idea of what price by noting that the price charged for the Tesla electric car in California is $100,000. Only posturing Hollywood types are willing to pay that price. Quite likely GM would have had to sell the EV1 for $50,000 to $60,000 in 1992. The number they would have sold at such a price would have been minimal. Therefore the decision to not to produce the EV1 was quite reasonable and rational. Apparently GM set a list price of about $34 thousand for the EV1 but they did not sell any because they did not want to do so. A $34 thousand price in the early 1990’s is about equivalent to $50 thousand in 2012.

However the way GM closed out the program was not reasonable or rational. GM called in the EV1’s from drivers who desperately wanted to keep them and GM hauled them to Arizona and crushed them. GM inanely called it recycling. It was a public relations disaster for GM. Alternatively GM could have auctioned them off for probably $20 to $30 million and saved the significant cost of transporting them to Arizona and crushing them. The sales contract could have stipulated that GM would not be responsible for any future costs or accidents due to design flaws of the vehicles. Instead GM incurred a lasting reputation for sabotaging the electric car.

I’ve said it once, and I’ll say it again: I believe GM has the most overall engineering talent of any automaker. If tasked with building a great car, GM will blow the world’s mind. But the problem has always been decisions made not at the engineering level, but at the executive/product planning level. It has always seemed to me like there are amazing engineers eager to make things happen, but product planners/execs who don’t know which cars to build and when. If only the Ford product folks responsible for genius like the Maverick and Bronco and F-150 Lightning were at GM, I cannot imagine the amazing machines we’d have on the road right now.

Three Binders Filled With Gold

But I’ve digressed. It’s time to talk about the hyper-rare GM EV1 service manuals I’ve attained through a back-alley deal out of a 1987 Cadillac Cimarron’s trunk (actually, a gentleman named Bryce Nash was kind enough to sell me these after storing them for decades. Thank you!). Look at these things:

Bound in Saturn binders (Saturn dealerships were in charge of leasing the EV1s, and in some ways the EV1 feels like a Saturn, with its composite body panels), the books cover the following topics:

- Battery and charging system; body repair; body collision

- HVAC; electrical; general information/specifications; special tools

- Propulsion system; brakes; chassis, miscellaneous

I haven’t read through all these books, as they’re about 1,000 pages per binder, but I have leafed through them and gazed at a few images I’d never seen before. Let’s get into it.

A ‘Pedal Feel’ Emulator For The Electric Braking System

Let’s start with the brake system, which is actually quite fascinating. The front brakes are electrically-assisted hydraulic brakes, and you can see the hydraulic lines in the graphic above. The rear brakes, though, are fully electric.

Basically, the EV1 used a brake controller, which works with the “propulsion control module” (this decides when the drive unit’s motor acts as a generator) to blend friction braking and regenerative braking “to maintain consistent braking as commanded, while maximizing the amount of energy returned to the battery through generation.”

The diagram and text below this graph walk through how the electro-hydraulic (front) and electric (rear) brake system works. It’s quite fascinating, utilizing a “pedal feel emulator” (presumably this one developed by GM’s then-in-house supplier Delphi), which features two spring rates (a soft and a hard) to ensure that the brake pedal force-to-travel relationship looks somewhat similar to this curve (this curve isn’t from the service manual, but rather from the previously-hyperlinked Delphi paper):

The way I’m reading this, the system reads pressure in the brake master cylinder to understand how much braking the driver is asking for. The actual brake hydraulics are closed off via solenoids such that the pedal isn’t actually pushing the fluid through the lines to clamp the front calipers. Instead, the brake fluid pressure reading is fed into a control module, which then decides how much current to send the rear electric brake and front electro/hydraulic actuators:

Air-Cooled Lead-Acid Batteries And A Heat Pump

Since I’m going in no particular order, let’s take a look at the EV1’s 312-volt battery back, shall we? It was T-shaped, not unlike the Chevy Volt’s, and featured 26 twelve-volt lead-acid batteries that totaled 16.5 kWh in capacity (in early models like the one shown here):

You can see there are two stacks of batteries with isolators between them:

They’re all air cooled, with a blower motor at the rear of the battery pack, down below, sucking air from ducts at the front of the bulkhead in certain conditions and through the heat pump in the dash under other conditions:

The image above shows air entering through the HVAC heat pump inlet, though you can see the exterior air ducts, which route downward from the bulkhead, here:

Here you can see the housing for the rear blower motor, which is attached to the backside of the battery pack:

Here’s a diagram of the entire cooling system, including the heat pump:

You’ll notice that in the dashboard (that’s the loop on the bottom right of the image above), there’s a “48 volt PTC resistive heater” on the other side of the evaporator. That’s there to assist the heat pump in warming the cabin, when needed. “The interior is heated by a 48 volt PTC resistive heater and heat pump active when any of the ‘HEAT MODES’ are selected on tehrun/lock shifter assembly (RSA) and the outside temperature is less than or equal to 15C (58F),” the service manual reads.

Front Cooling Module

Here’s a closer look at the cooling module at the front of the vehicle:

The Electric Motor Drives The Front Wheels

OK, since this article is on the verge of being a 5,000 word nerdfest (as an engineer, I can’t help it!), I’m now just going to blast through a few other sections of these service manuals without getting too deep into it. Let’s look at the drive motor, which powers the front wheels. To get to it, you have to look under the hood, where you’ll see a “front compartment sight shield.”

Remove that shield and you’ll see the Drive Motor Control Module (DMCM), which has “GM” cast into it:

Removing that DMCM reveals the drive motor in its full glory:

The drive motor consists of an AC induction motor sending up to 137 horsepower and 110 lb-ft of torque through a 10.96:1 (per Motor Trend) single-speed transmission whose output shafts are parallel to the motor’s axis, just like what you’d find in a modern Tesla. Sadly, the repair manuals don’t seem to show the guts of the motor.

The Motor And Power Electronics Are Liquid Cooled

Both the drive motor and the power electronics mounted atop it (the DMCM) are really the only liquid-cooled components in the entire vehicle. See diagram above and the entire cooling system diagram from before.

Because I’m sure you’re curious, the water pump — mounted right near the driver’s side front wheel liner, contains a manifold that one uses to drain the cooling system:

A Solid Rear Axle, An Independent Front Suspension

Let’s look at the suspension:

That’s a five-link, coil-sprung solid rear axle out back with “aluminum end castings and a tubular center section.”

And here’s a look at the front suspension:

As it states, that’s a short/long-arm independent front suspension with a coilover.

Electrohydraulic Power Steering

Now let’s have a look at the steering setup:

The EV1 utilized an electrohydraulic power steering system, meaning there was an electrically-powered pump that compressed power steering fluid and forced it into the steering rack to provide steering assist. This electrically-powered hydraulic pump was mounted to the subframe rail on the passenger’s side and was accessed via the wheel liner:

While an electrohydraulic steering design was fairly novel at a time when everyone simply used their gasoline engine’s accessory drive to power their hydraulic power steering pump, it wasn’t a first, as even the late 1980s Toyota MR2 had such a system.

A 12-Volt Battery Under The Hood

You may be curious if the EV1 had a 12-volt battery like today’s EVs do, especially since the car’s high-voltage pack was made up of a bunch of 12-volt cells. The answer is yes; GM needed a 12-volt system to power the various electronics (wipers, interior lights, headlights, etc.) so they did what modern EV makers do, and installed a tiny 12-volt battery that’s charged by the high-voltage battery via a DC-DC converter (integrated into the DMCM). Here you can see that 12-volt battery mounted to the bulkhead under the hood:

There’s So Much More In These Amazing Historical Documents

There’s so much more in these books that I haven’t even glanced at yet. Check out the shifter!

There’s also lots of info on the ducting under the dash:

Here’s the special triangular tool you need to remove the drive motor:

Here you can see the car’s jacking points:

Here a look at various harness routings:

Here’s an up-close of the water pump:

Check out how the car uses a datum to place each part of the body into an X,Y,Z coordinate to help body-shops make repairs:

= =

Here’s the front cradle/subframe:

Here’s the front end module:

And here the service manual is discussing repair procedures for plastic panels:

I’m excited to keep diving into these service manuals, but I’m already amazed by what’s in here — it’s a truly detailed, granular look at the technology that went into America’s very first viable electric car. This is a rare glimpse at automotive engineering history.

Does anyone know how much time (ms) it takes to disconnect the battery automatically from its electrical system after the crash?

I saw no mention of the thermoplastic battery tray?

What a find, really. I hope you’ll have the time to read it properly.

The interior door handles and door lock switch are from the first-gen Saturn S-Series.

I’ve seen the original prototype at the GM Heritage Center, but mixed in with everything else there, it doesn’t have the “Impact” it otherwise might…

I had the privilege of ogling one of these, as there’s one in the lobby of the engineering building at New Mexico State University, my alma mater. GM had several recruitment programs at NMSU up until 2006 or so, and donated an EV1 as a museum piece in 2005. We tried like hell to get the dean to let us use it for a capstone project, but I’m told the donation clause mandated no usage whatsoever.

It was genius, especially for the time. too bad GM never actually sold them and just scraped them when they were done with them.

I’d really be interested in reading a breakdown of the design of this car by Adrian

There exists an EV1 at the Henry Ford in Dearborn. I was there last year and saw it. I think it is one of two or three that were spared for historical purposes. I don’t recall if their unit had all of the electrics and mechanicals intact though.

There was one in the visitor’s lobby of the security building at GM’s Lansing Delta Township assembly plant for a while in 2022. Unfortunately I only saw it a couple of times before I got a badge and didn’t need to check in there every morning. Next time I did go back in, it was gone. No idea where they took it, and I wish I’d taken a couple pictures, but it was very early in the morning, so it was pretty dark in there.

That’s a great museum, probably one of my favorites. I was stunned that I was actually seeing an EV-1 in person, even more stunned to see a Tucker Torpedo about 5 minutes later. And not much longer after that, I got to go inside the Rosa Parks bus. The village area is fantastic too, I love how they brought whole-ass houses of historical significance (Wright Brothers home, Edison’s workshop, Henry Ford’s childhood home, etc.) from around the country and set them all down in one place. Between the historic buildings, working farm, the steam locomotive running around the property, and the Model Ts driving around, it felt like a genuine time warp.

These are like the Dead Sea Scrolls for EVs, only in much better condition. It’s great that they found a good home!