Rust was once the bugaboo of every car owner in the land. Eventually, technology improved, and now it’s largely a solved problem for those in drier communities, at least. For modern Jeep Wrangler owners, though, corrosion in another form is rearing its ugly head. It’s all about aluminum.

The issue concerns bubbling and flaking paint and corrosion, most commonly seen on the door hinges and door panels of affected vehicles. The blight affects both the JT Jeep Gladiator and the JL Jeep Wrangler, and can seemingly affect any of these vehicles built from 2018 onwards. In turn, this common pain point has become a topic of much discussion on forums and beyond.

Corrosion is one problem, but for many owners, the response from Jeep has only compounded the issue. Scores of customers have reported their issues to dealers, and many have been left frustrated and unsatisfied in turn. So what’s going on?

Corrosion, But How?

The modern Wrangler (and Gladiator in turn) picked up a number of aluminum components in the latest generation. The aim was to cut weight and improve efficiency in turn. The JL model hit the market with an aluminum hood, tailgate, and doors, while the main chassis still relied on steel.

By eliminating the use of steel in these components, there’s no risk of rust, but that doesn’t mean there’s no risk of corrosion. Typically, it naturally forms a hardy aluminum oxide barrier on its surface. Unlike iron oxide, this layer is tough and remains bonded to the base material. However, under the right conditions, aluminum can still suffer deleterious corrosion. Still, if properly painted and prepared, an aluminum panel should hold up to regular environmental conditions with little to no corrosion for many years.

In the case of the Wrangler, though, corrosion is popping up in vehicles just a few years, or even months, after delivery. This corrosion is most typically seen as bubbling on the door hinges, or on the door panel in the surrounding area. Other common areas include the lower part of the door panel itself. In mild cases, small bubbles under the paint aren’t particularly noticeable, but the problem can easily progress to the point where large chunks of paint are flaking off entirely.

One of the prime ways that aluminum can corrode is when it comes into contact with a different type of metal. This is referred to as “galvanic corrosion” or “dissimilar metal corrosion.” This has led to a widespread belief in the Jeep community that the hinges themselves are the problem. Endless videos and forum posts claim that Jeep’s combination of steel hinges with aluminum doors is the root cause of the corrosion issue.

However, a reality check suggests that’s not entirely accurate. The simple fact is that the JL Wrangler’s door hinges are made of aluminum, not steel. Furthermore, if that were the source of the issue, Jeep’s engineers could have solved the issue years ago with a simple part substitution. Some have suggested that the steel door bolts are the cause, but it’s not a likely explanation. Particularly given many owners are seeing corrosion and bubbling occur in areas like the lower door panel, where there are no fasteners or steel parts at all.

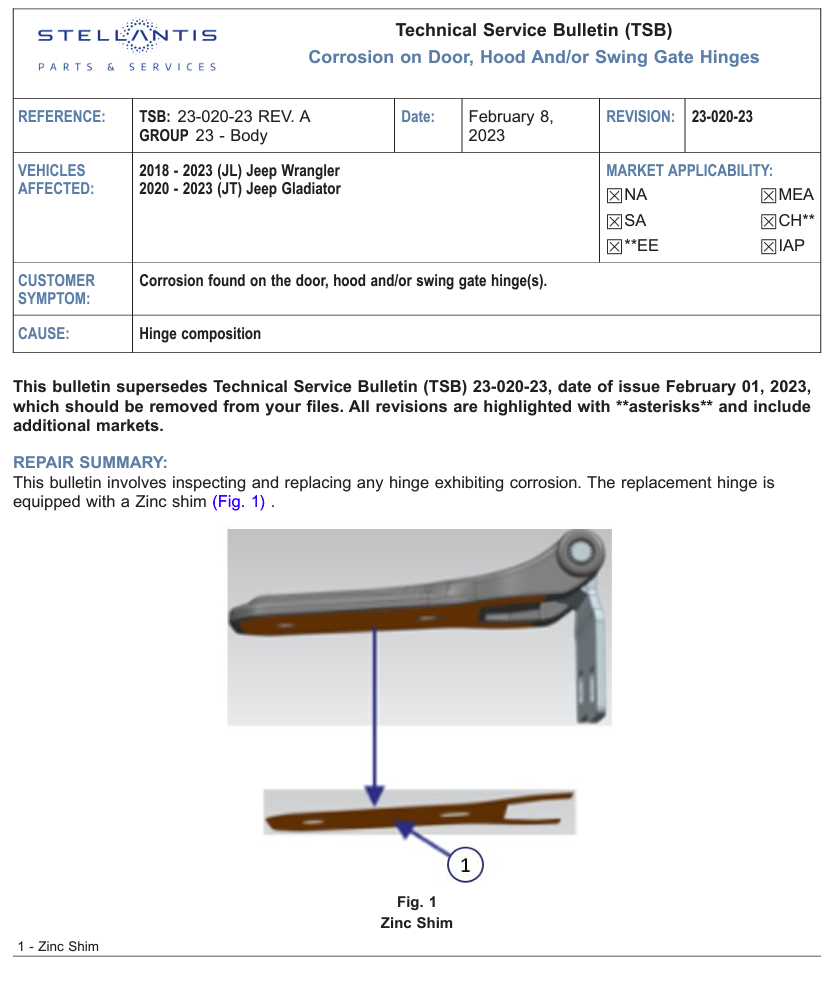

And yet, a move from Jeep to rectify the issue has added fuel to this common theory. In February this year, Stellantis issued a Technical Service Bulletin (TSB) regarding the matter. It instructs technicians to replace any corroded hinges with a new part that comes with a zinc shim. Zinc is often used as a “sacrificial anode” on submerged metal parts on ships. Thanks to Zinc’s greater potential for oxidation than metals like steel, it preferentially corrodes while leaving the structure intact. It hints at a galvanic corrosion issue at play here.

Jeep Blames The Aluminum Door And The Manufacturing Process

Here’s what a Stellantis spokesperson told us:

Model-year 2018 migration to an aluminum door design – a weight-saving measure – inadvertently coincided with, initially, occasional variation in the manufacturing process.

The issue described may occur in a fraction of these vehicles. Accordingly, we are providing affected customers with a solution.

It’s true that zinc will typically preferentially corrode over aluminum or steel. However, in this situation, having the shim corrode between the door and door hinge would be undesirable. It would lead to the hinge/door interface becoming loose over time, and there would still be unsightly corrosion byproducts, to boot. It could simply be a method to delay corrosion of the hinge/door area, rather than to stop it entirely.

Stellantis essentially confirmed this, saying: “The shim helps mitigate material properties that may induce corrosion.”

There are many related theories that are floating around various forums, some of which are more believable than others. Some suggest that Jeep’s paint process for its aluminum panels is not up to scratch. They suggest airborne contaminants, perhaps even tiny iron particles, are getting under the paint and causing the corrosion problems. That’s plausible, particularly given that it would fall under an “occasional variation in the manufacturing process” and this problem seems to have started for Jeep with the advent of the aluminum panels used in the JL and JT models. Indeed, Jeep’s own TSB for the repainting procedure states that “When sanding and prep is done you must use clean sanding pads and in a separate room from ferrous metals, as cross-contamination will lead to galvanic corrosion.”

Another theory suggests that the problem stems from the fact that Jeep paints the doors with the hinges already installed. Thus, there’s only a minimal primer coat, if that, between the hinge and the door. Thus, when water or other contaminants get into the hinge grooves, the corrosion problem begins. This could be plausible, though it doesn’t explain corrosion in other areas like the lower areas of the doors. It’s also likely that bolting together a fully-painted hinge and door would damage the paint anyway.

Repair And Despair

Naturally, customers are seeking repairs to their affected vehicles. Jeep offers a 5-year, unlimited-mile warranty for corrosion, so a great many owners have pursued a warranty repair on that basis. Repair involves either sanding down the affected panels and repainting them, or replacing them entirely.

Sadly, many have been frustrated by delays and poor repairs. Talk to owners on the JL Corrosion Information group, and they’ll tell you it’s been an unmitigated boondoggle.

Scott Anderson bought his 2019 Jeep Wrangler used in December 2023, picking it up in Tremonton, Utah. Having discovered corrosion on the vehicle, he headed to a local Jeep dealer to get the problem seen to. “They said I needed to go get a quote first from the body shop, as they did not have an in-house shop there,” says Scott. That would turn out to be a mistake.

“Because I got the quote first, it put me 2 days out of warranty,” Scott explains. He was told to contact the Jeep Cares customer assistance line, and he says he was told twice that the issue would be covered. “I had the appointment, and took it in on a Monday,” he says. “At 10 on that Monday they called and said they will not cover the repairs.” He’s followed up multiple times, to no avail. “Now when we call and give them the VIN, they hang-up,” he says. “First time Jeep owner, and last.”

Toddy Spencer is based down in Illinois, and he’s seen the same problems up close. “Mine is a 2018 so I caught right in time,” says Todd. “My corrosion is just on my hinges for now.” He knows he’s not alone, too. “I work for a dealership, and I see corrosion on almost all of them,” he says. As it stands, it’s looking like he’ll get his Jeep sorted by the factory, but there’s a wait involved. “I made a warranty claim back in February and I’m approved for all new door hinges, but parts are so backordered it will be another 6 weeks before they get to mine,” he says.

Complaints of delays abound, along with customers getting the runaround from Jeep Cares and dealerships. Average wait times seem to hover around 6 months to a year for those wanting a solution. Color match issues for repaired vehicles have also hounded some owners.

In fact, the more I kept digging, the more stories kept coming out of the woodwork. Ashley Dalton shared the photo above, showing a significant color-matching issue. “Many [body shops] do not blend into adjacent panels to achieve a decent paint match and hope the customer doesn’t notice,” Ashley told me. “Notice they didn’t blend into the adjacent panel so you can clearly see the mismatched paint at the edge of the door.”

Meanwhile, Paula Kay suffered warranty woes with her badly degrading white Wrangler. “My biggest issue with this is that I was told by Jeep Cares that they will not give me one cent due to being out of warranty, yet every day on here I see people out of warranty getting cost share assistance,” she says. After having an inspection appointment set up with a dealer, she says Jeep wasted her time by not even looking at the pictures taken by the service manager. “How do they pick and choose who they assist when out of warranty?” she asked.

As it stands, it appears a significant proportion of JL and JT models are affected. Used buyers would do well to carefully inspect any vehicles of this generation, and new buyers would be well advised to pay close attention to any warning signs on the paint.

It may be only a cosmetic issue, but it’s one that has seriously pissed off a great many Jeep owners. It’s not unreasonable for them to expect a five-year-old car to keep its paint intact. Much like the manual transmission issues Jeep has faced of late, it’s another case of Jeep failing at the very basics, and stumbling on repairs to boot.

(Image credits: Todd Spencer, Scott Anderson, Tristan Ray Geddes, Ashley Dalton, Paula Kay, Jeep)

Support our mission of championing car culture by becoming an Official Autopian Member.

-

Here’s Why You Might Not Want To Buy A Third-Generation Toyota Prius

-

The Popular BMW B58 Inline-Six Engine Has One Big Achilles Heel

-

Here’s Why Busted Plastic Grille Flaps On A Newer Car Can Cause A Check Engine Light

-

If You Want To Buy A Cheap Jaguar, Here’s An Engine You Should Probably Avoid

-

Honda Pilots Only Just Stopped Featuring This Ancient Engine Technology That Most Cars Abandoned Over 50 Years Ago

Got a hot tip? Send it to us here. Or check out the stories on our homepage.

Dad had a 1990 Lincoln Town Car, midnight blue. When the car hit about 8-10 years old, all the paint just fell off in sheets! Apparently was a paint/primer bond issue from the factory. Was fairly common issue on dark blue and maroon Ford and GM product from about 1988 to 1992.

White Town Cars had that issue until the end of production, could start as a little stone nick in the hood, then the paint on the entire panel would just peel right off. At least it seemed to be mostly with the white paint, not sure if it affected other colors as much

We used to pick paint off my sister’s blue Chevrolet Beretta when we were bored.

It may have had something to do with the transition from VOC to water-based paint. Chrysler had the same problem during that time.

I think I remember hearing that, yes.

There was more to it back in those years. Steel suppliers talked the auto industry into using pre galvanized steel for body panels. This new coating (they claimed) eliminated the need for primer, which the bean counters jumped at..and you picked at the results.

It was a great thing for the precision sheet metal business, but our products were usually used indoors. It still has disadvantages with respect to spot and TIG welding, but rivets and adhesives made up for that.

Powder coating was just getting off the ground then and that helped for parts that were used outdoors.

Mazda had the same problem.

Is it finally time to crown Stellantis as the new British Leyland? It seems like we’re awfully close.

Corrosion issues (all aluminum, rusty trucks), reliability issues (Hornet, 4xe, etc), and vehicles they just. can’t. sell. even with 20%+ discounts. Regardless of how you feel about their vehicles, now is not a great time to be a Stellantis Stock Holder in my eyes.

I’ve been seeing news headlines about multiple Stellantis executives jumping ship as well. I’m wondering if we are about to see a full-on corporate implosion.

It’s wild just how badly they misjudged their North American product mix (such as it is). They managed to put together a lineup that nobody wants for prices nobody wants to pay.

Looking at the prices at my local dealer: $7,000 CAD on the hood for the Grand Cherokee. Over $6,000 CAD in discounts on some models of Wrangler (and that’s usually their desirable model!). Some models of Compass have $5,000 off (and that’s the cheap one!). They have a leftover 2023 Grand Cherokee with $19,000 worth of discounts! And it’s still somehow over $70k! And who do they think is spending $150k CAD on a Grand Wagoneer L!?

Global Leyland

The aluminum hood on my 2019 RAM is doing the same thing unfortunately

This article, it’s like deja vu all over again.

Welcome to the party JL Owners. WK2 owners have kept the chairs ready for you.

WK2s (Grands from 2011-2022) suffer from the same type of issue on the leading edge of the hood. My 2011 has corrosion at the hood’s edge for as long as I remember. I reached out to Jeep Cares years ago (I think 2017) and it was already out of warranty at that point. They also claimed that because I wasn’t the original owner the warranty didn’t cover me, but whatever on that.

This has been documented for some years and has impacted the entire model run.

From what I’ve read, is that this bonding issue with the aluminum under the hood. In turn, it corrodes right along the edge. I don’t know if anyone has exactly put a finger on the root cause though.

The PROPER/traditional way to do aluminum on a Jeep body is with diamond plate:

https://i.ebayimg.com/images/g/2JYAAOxyRhBS3dY7/s-l1200.jpg

https://www.ebay.ca/itm/115666217639

It’s a Jeep thing that these new Jeep owners clearly don’t understand…

lol, that is usually a cover up of existing regular rust and in fact increases the problems when the rust/steel react with the aluminum when moisture gets between them.

Agree.

“It’s a Jeep thing, you wouldn’t under

coatstand.”For the suppression crowd: This version of the article is significantly more extensive and, well, better. Feels more like it was pulled because it wasn’t done yet.

We published it early by accident. The folks at Stellantis asked us to hold the piece until they could get back to us on Monday (today) but we forgot to tell the holiday crew to pump the brakes. So, it was published without the additional context. We pulled it because we didn’t mean to agree to hold publication and then publish anyway.

Either way, it’s always great when we can add even more value to a piece, as shown here. 🙂

OMG thank you! I was soooo confused thinking there was some kind of wacky Mandela effect going on.

It’s BAAAAACK. Good journalism shall not be suppressed.

It’s back!

Great business opportunity: sell paint-bubbled ducks for people to award to one another while waiting for resolution.

Landrover has fought this issue for decades, especially on Defenders and Discoveries. The older models used a lot of galvanized parts that preventedit but when Defendersswitchedto painted body cappingthey started corroding. .

Jeep should probably be using a plastic or rubber hinge shim, since the most successful fix for Defender doors was an aftermarket part with a powder coated steel frame that insulated it from the aluminum door skin.

Glancing at my ’23 gladiator it looks like there may be a plastic shim between the hinge and the door panel. Definitely something there. I’d like to see disassembled hinges from affected vehicles to see if there is the same thing

If I had a Wrangler I’d name it Jane, so it’d be Wrangler Jane like the girl in “F-Troop.” Just thought I’d throw that out there even though it has nothing to do with rusting Jeeps. It’s Friday, things are kinda slow …

Ya know, maybe they should’ve bought that electronic rust proofing thang that the F&I guy was shilling.

If only they used stainless steel, cause that doesn’t rust.

I mean, it does corrode over time. It’s better than plain steel, but not “rustless” steel.

It was a tongue in cheek comment, and the article got pulled before I could edit.

Oh shit, sorry about that.

an OTA update should fix this

Dissimilar Alloys = Slightly Different Electrical Potentials = Galvanic Corrosion?

What’s directly behind the raised areas on the door? Is there some kind backing plate that’s a different metal/alloy?

The corrosion seems to be always near areas that were stamped, folded, or stretched. Could those processes be introducing some defects in those surfaces? It almost looks like stretching the aluminum changed the surface in a way that makes it more susceptible to corrosion.

Is heat somehow involved?

I also assume they are skipping some paint prep steps that others like Ford and JLR are using.

This is a weird one.

I can see the metal working causing problems as they’d typically be using a tool steel, however given how soft aluminum is and how it likes to “stick” to things I’d expect that to be a problem for the first 20 or so parts made on the machine before it has so much aluminum coating it it doesn’t really transfer or embed itself into the metal. The tooling will start to rust however…

One other idea is there’s a bad / missing ground for something like a door actuator, windows, speakers, etc. and it uses the door as a ground. Passing electricity through dissimilar metals speeds up the galvanic effect a lot.

I was wondering along similar lines. Like are the die forms leaving iron molecules on the aluminum? But as you point out, it should be the other way around.

Love the bad ground idea! However, I would think that should be quickly testable with just a multi-meter. My assumption is that with all the metal to metal contact, the door panel should be well bonded to the chassis.

It happened a lot when Corvair owners disconnected their ground straps when removing a powerplant and didn’t reconnect them. The next ground path was the clutch cable…

Cold working of metals does induce shifts in the local electronegativity of the worked areas. These shifts are generally not enough to induce corrosion by themselves in an electrically isolated part, possibly with the exception of being in a marine environment or in some rare atmospheres.

But in a galvanic corrosion scenario with two dissimilar metals, if the cold worked areas are pushing the elecronegativity in the direction of being even further from that of the other metal, those areas will corrode preferentially. I forget whether cold work raises or lowers the electronegativity value.

“It’s a Jeep thing, you wouldn’t understand.”

There is a simple rule of thumb when looking at a prospective jeep purchase, “If it isn’t six in a row, let it go.”

That’s my BMW purchase mantra. For Jeeps it’s ‘8 is great’.

My bmw is a boxer 2. But one day I hope to have a straight six z3, to continue my james bond collection.

Head down to your local marina and pick up some sacrificial anodes that normally go on boats. Hang ’em out back like truck nutz and viola! Problem solved.

But that would ruin the viola…

Sorry, couldn’t resist.

I’ve fought rust on four of my last five vehicles, as well as my current 2017 Pacifica which has the pretty common bubbling on the edge of the hood. I live in the rust belt so it’s to be expected… but nothing makes me feel more defeated than seeing rust pop up on a fender or hatch. I can handle a consumable part going bad, but rust is a cancer that in most cases cannot be stopped; just contained.

I can’t imagine a reason I’d shop for a Jeep, but regardless, this article right here just crossed JL’s from my mental list permanently.

It’s one reason I generally love aluminum bodies and aluminum chassis, provided you use good aluminum to avoid intergranular corrosion, and you do your best to avoid dissimilar metal corrosion, aluminum is a great material for humid environments.

Having been around Land Rovers all my life dissimilar metal corrosion is a massive issue. I’ve seen it “rust” through aluminum panels like rust through steel panels.

Something this may be that I haven’t seen mention of yet is Intergranular Corrosion. I’ve seen similar paint bubbling on tons of Land Rover Defenders, with no apparent origin. Apparently it’s Intergranular Corrosion.

I’ve been looking at getting a new Wrangler for years. If I ever do buy one the first thing I’m doing is removing the doors, hood and tailgate and selling them. I know a great composites guy who could make me a killer custom carbon fiber hood for the Jeep if need be.

Does “Stellantis Product Suffers Serious Quality Issue” even count as news anymore? Seems like it’s more in the vain of “Dog bites mailman” than “‘Mailman bites dog” by now.

“Bad Thing Happens with Boeing Plane.”

It sounds like a lot of owners selected the David Tracy Appearance Package when buying their vehicles.

Was DT involved in the decision to publish this on Friday afternoon of a holiday weekend?

Even funnier to think this now

I had the same problem on a Ford Mustang I bought new, paint on the trunk lid started bubbling off at 3 years, I repainted it out of pocket because Ford wouldn’t cover it under warranty as it wasn’t technically “corrosion”, being aluminum oxidation. Then it happened more prominently on the hood, Ford again offered no help, so I paid to put a new one on, since I figured the original would only bubble again if the shop didn’t clean and prep it properly, then the trunk started bubbling a second time, so I traded it in on a Dodge Challenger

I would be curious to hear Ford’s lawyers parse the distinction between “corrosion” and “oxidation”.

Apparently, their warranty deals with perforation, a chemical reaction between aluminum panels and iron contaminants that blisters and peels the paint won’t, or isn’t likely to, perforate the panel, so it falls under the mileage capped comprehensive warranty instead of the more generous corrosion warranty

Trouble is, the time it takes for the issue to become visible is typically right at the edge of the comprehensive time limit, which means most cars will also be over in miles

The dealer said they had had some luck getting Ford to do goodwill repairs on F-150s and Explorers with similar issues, but Ford was pretty inflexible on Mustangs. Probably because the problem was much more prevalent at the Flat Rock plant

Finally I can see and respond to this!

I wonder if that defense would hold up in court if someone really went after them over it.

Fingers crossed they’ve figured it out better on their aluminum trucks.

This article made me wonder whether there have been any corrosion issues with the much-vaunted aluminum beds on F150s.

My 2011 did the paint bubbles along the hood at 3 years old and the dealer repaired it under warranty with no issues. 10 years since then and it still looks fine. Bad local dealer?

Were you within the mileage cap? I had close to 70,000 miles at 3 years

I would have been way under. I can’t remember exactly but was probably under 30,000km at that point.