If you’ve ever had to rebuild an old Porsche 911 engine, you’d likely say that it’s a fiddly process. In an effort to make it easier, Porsche has been hard at work on brand new magnesium case halves for 1968 to 1976 Porsche 911s, and they’re now ready for the limelight. Talk about a change of pace from infotainment retrofits.

As you might expect if you’ve spent time around flat engines, the flat-six in the classic Porsche 911 uses the traditional arrangement of a split crankcase that’s bolted together once the crankshaft and con rods are inside. However, starting in 1968, Porsche decided to try switching from aluminum crankcase halves to magnesium units. This saved weight but introduced owners to some fascinating problems down the line.

Magnesium is a cool material. From vintage racing wheels to body panels to engine parts, this lightweight metal can be alloyed to produce some truly featherweight parts. However, it also has downsides. Pure magnesium along with certain early alloys is very flammable, vintage magnesium alloy wheels are particularly susceptible to corrosion, and some heated magnesium alloys can see a yield strength reduction at as little as 200 degrees Fahrenheit.

After enough heat cycles, the head studs would pull out of the case halves, necessitating a costly and time-consuming teardown to repair the threads in the case halves. Speaking of heat, those magnesium case halves were also prone to warping. Porsche seems to have known about this issue as later cases stamped 7R featured reinforcement, but all magnesium case halves are inherently finicky. After nearly a decade of magnesium case halves, Porsche switched to die-cast aluminum case halves for the 911 Carrera 3.0, a decision that stuck more or less for good. However, owners of older 911s still face issues of finding good case halves that aren’t corroded or hideously warped, cleaning them up at the machine shop, time-serting the head stud threads, and then putting them all together.

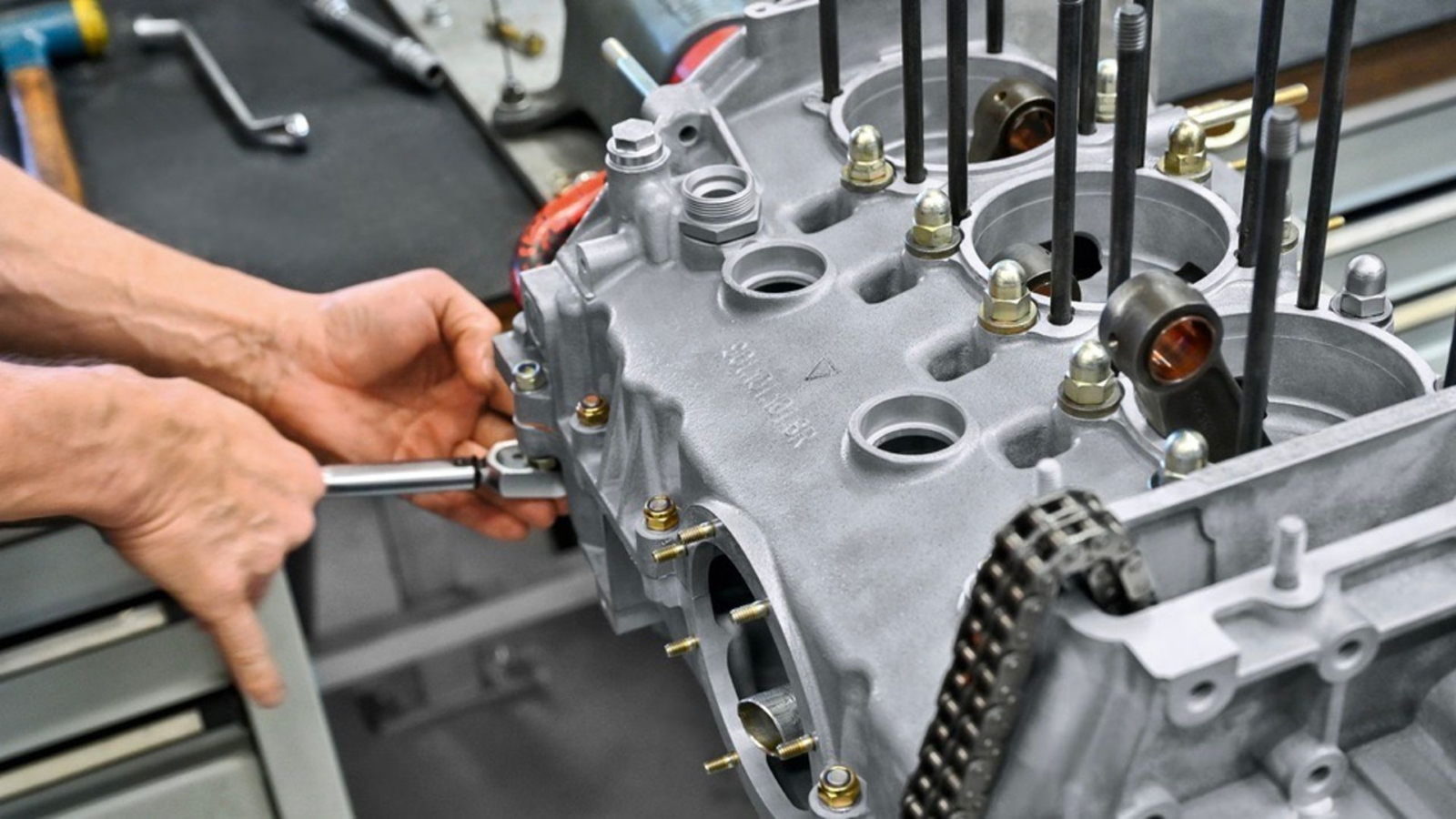

However, Porsche now has a solution that will save owners a ton of time – brand new magnesium case halves. From the sound of things, these weren’t easy spare parts to cook up. To start, Porsche pored over vintage technical documents and examined existing case halves to build CAD models. Once those were refined, Porsche sent the models off to a supplier for casting the old-fashioned way using sand. Molds are formed, cores are made out of sand and resin so metal doesn’t go where holes are meant to be, magnesium is poured into the molds, then the cores are thrown in the bin when the part is cool and ready. After the casting process, each case half goes into a five-axis milling machine for, um, machining. Mating surfaces are cut, pockets and holes are drilled and milled, and each case half is then sent off to quality control for measurement of 1,300 dimensions. How German does that sound?

Of course, building new case halves is one thing, but making sure they work in an engine is another. Porsche conducted several weeks of bench testing on the case halves as part of a Carrera 2.7 RS engine followed by tear-down and inspection were the next steps, with the passing case half designs only then going into limited production. In theory, these new case halves should be ready for whatever owners throw at them.

With a possible sunset for new mass-produced combustion-powered cars in sight and strong interest in classic performance cars, it’s not surprising that automakers are making new engine components for some of their greatest hits. Nissan put engine blocks and cylinder heads for the legendary RB26DETT 2.6-liter twin-turbocharged inline-six from the R32, R33, and R34 Skyline GT-R back into limited production in 2019. Mazda still makes parts for the 13B rotary engine from the RX-7. General Motors will likely continue to make small-block Chevrolet V8s until the sun collapses. It’s nice to see Porsche hopping on the train and providing vintage 911 owners with new magnesium case halves.

Oh, and in case you’re a Porsche owner on a water-cooled budget, I have some news for you. Porsche is developing a brand new sports suspension system for the 996 in collaboration with the legendary Manthey Racing. I can hardly wait.

(Photo credits: Porsche)

Support our mission of championing car culture by becoming an Official Autopian Member.

-

Put Apple CarPlay In Your Mid-2000s Boxster With Porsche’s New PCCM Infotainment System

-

Here’s How Badly Rusted A Porsche 911T Has To Be To Cost Under $9,000

-

Porsche’s New 357 Concept Is Supposed To Be An Homage To The 356, But It’s Just A Blob

-

Our Daydreaming Designer Attempts To Fix The Porsche 914’s Design To Appeal To The Haters

-

Porsche Netherlands Has Reincarnated The Legendary ‘Renndienst’ Racing Support Vans Of The ’60s Using An ID.Buzz

Got a hot tip? Send it to us here. Or check out the stories on our homepage.

Well, dang. This is certifiably Good Parsh.

Oh, and in case you’re a Porsche owner on a water-cooled budget, I have some news for you. Porsche is developing a brand new sports suspension system for the 996 in collaboration with the legendary Manthey Racing. I can hardly wait.

you have my undivided attention

One of my favorite magnesium burns https://simson.net/ref/1993/cubefire.html

Just keep the the rust guy well clear of it ’cause weird stuff can happen.

Can’t they just use aluminum blocks anyway? Some Porsche owners like to swap in Subaru engines.

Rear engine cars are popular for EV conversions, too

My thoughts also. It’s not like losing a few kilos would kill performance.

This is mostly about keeping customers happy

$ 12,283.81

There is no way they’re making money on this. No. Way. This is the kind of commitment to a car… well I guess since we’re talking about a car that arguably dates back to the 30’s, I get Porsche having a sense of history and duty to vintage owners. As an Engineer I admire this, but as someone pointed out it is at least a few tiers above “first world problems”..

I was thinking the same. I will laugh my ass of in 40 years (provided I’m still around) if I see them do the same for owners of current generation Cayenne mall crawlers.

To be faaaaaaair, Porsche has a surprising amount of parts still out there for the 944, a car that can still be had for three figures if you know the right places to look for total basketcases.

I can absolutely see them supporting the Cayenne, and they’d be silly not to given all the fun off-road builds going on with that platform nowadays.

Given the “fuck you, try to put this fire out” properties that you mentioned in another comment, is the garage the best place to store it? Although, TBH I couldn’t tell you where a safe place to store a LOT of high purity magnesium would be.

A reasonably safe place is in someone else’s garage.

I looked up “class D” fires and found out **** me ,plutonium burns?!

Just don’t keep any chlorine trifluoride around and you’ll be fine.

https://www.science.org/content/blog-post/sand-won-t-save-you-time

…brand new magnesium case halves for 1968 to 1976 Porsche 911s…

What’s two levels up from “First World Problem”

Ummn, needing a period correct radio?

A period correct radio *knob*.

You laugh, but…………{ incoherent mumbling about soft-touch plastics that get sticky over time }

I hope they put inserts in the head stud threads. Porsche did factory install helicoils in the sparkplug threads in the early 70s. I actually saw that on a project car which involved a rust free 911T shell with the engine in several milk crates. The heads survived, the cases were usable, and the pistons were scrap because the cast iron rings rusted, swelled, and blew the rig lands off

“…this lightweight metal can be alloyed to produce some truly featherweight parts.”

That’s among the reasons I run with a magnesium cargo box on the roof. Keeping the weight down (and the center of mass low) helps with cornering and, in general, staying ahead of the competition:

https://live.staticflickr.com/65535/52733903562_5af0bfde83_o.jpg

More companies should do this kind of thing, and for more than just engine parts.

To use a personal example that’s aggravated me lately: for how popular the 67-72 C10/K10/K5 Chevy trucks/Blazers/Suburbans are, it’s ludicrous how difficult and expensive it is to locate original seats. It seems like an opening for GM. The same can be said for a lot of small trim pieces or interior parts.

That and the gorgeous seat upholstery in the American cars from 1960s to 1970s, namely Cadillac. Today, no upholstery specialist has them in stock, and no manufacturers would replicate them. Many of vintage American cars had the upholstery replaced due to wear or damage with plain ones.

I look forward to on-demand manufacturing, like 3d printing, getting to the state where good quality pieces are relatively affordable without a manufacturer having to produce a huge inventory.

I have an Avantime, and all those various pieces that didn’t appear on the Espace can be hard to find or afford.

Meh, just LS swap them…. ;P

I think it’s worth noting that while magnesium is flammable, it’s mostly dangerous only in powder/shaving/ribbon form. Similar to how a 2×4 won’t immediately catch fire compared to sawdust.

I used to run a lathe machining magnesium and titanium. If the coolant got low or the nozzle wasn’t directed properly and a hot chip got in the scrap barrel it was time to grab the fork lift and rush that thing out into the parking lot.

Come to think of it, that machine shop eventually burnt down (long after I worked there).