If I asked you to think of a car with weird windshield wipers, what would you suggest? Perhaps you’d mention the Tesla Cybertruck, with its massive swooping blade, or the triple-arm setup on the glorious Toyota FJ Cruiser. But there’s an altogether stranger solution out there, from one of the most conventional automakers on the block. I’m talking about Ford and its powerful wiper systems from the mid-1960s.

The vast majority of windscreen wipers work in the same way. They use an electric motor of conventional construction, paired with some gearing and linkages to create the appropriate back-and-forth swooping motion that clears your windscreen of water. Electric motors make sense—they provide enough torque and power to do the job, and powering them is as simple as running a couple of wires.

However, if there’s a way to overcomplicate a system and increase the likelihood of leaks and failures, you can bet at least one automaker has tried it over the years. That’s what led Ford to develop an all-hydraulic windscreen wiper system.

Pump, Pump It Up

Today, we take windscreen wipers for granted. At the flick of a switch, we can have them swishing back and forth to clear the view ahead at a range of speeds to suit our desires. However, it wasn’t always thus. In the earlier days of the automobile, wipers weren’t nearly so good.

A full history of the windscreen wiper would be too long and tedious to explore here. Suffice to say, in the earlier part of the 20th century, there were two major types of wipers used across most of the automotive industry. Vacuum-powered wipers were popular with many automakers, relying on vacuum generated by the engine itself to power the wiper motors. This was an imperfect solution, as wipers would slow when engine vacuum was low—such as when throttle was wide open during high-speed driving or during a hill climb. Wiper speed control was also difficult to achieve; it wasn’t even considered as a feature in this era.

Vacuum wipers: universally considered to be a bit crap.

Alternatively, some brands, like Chrysler, instead chose to adopt electric wipers as early as 1940, which didn’t suffer this problem. Meanwhile, a more obscure solution was to go the mechanical route. The early Citroen 2CV was an example of this method, running its wipers off a cable hooked into the transmission, along with the mechanical speedometer. [Ed Note: Some Willys Jeeps ran wipers off the vacuum created by the mechanical fuel pump. These were failure prone. -DT].

Come the 1960s, though, Ford went a rather unique route of its own. It decided that windscreen wipers should be hydraulically driven—with hydraulic power supplied by a vehicle’s existing power steering pump! Ford most notably used these on the 1961 to 1969 Lincoln Continental, the 1963 to 1971 Ford Thunderbird, and select models of the 1969 to 1971 Lincoln Continental Mark III.

This method had a number of benefits. For one, an engine-driven power steering pump could provide plenty of excess power to run the wipers. There would be no issues with weak running at speed like vacuum wipers, since even at idle, the power steering system would have plenty of hydraulic pressure on tap. This was particularly useful for drivers in snowy climates or those with heavy rain, where powerful wipers are a big help.

Variable speed operation was also straightforward, simply by metering the flow to the hydraulic wiper motor. The concept was not altogether different to Jeep’s hydraulic cooling fans used in the early 2000s. The power steering pump was a straightforward source of hydraulic power that could be used to run a simple mechanical accessory.

However, hydraulic wipers also had their drawbacks. They required running hydraulic lines from the power steering pump up to the cowl, where the wiper motor was mounted. This was messier compared to electric wipers, which just required a couple of thin wires to run to the cowling. Extra lines attached to the power steering system meant there were more hoses to potentially leak. It also meant that if the power steering pump failed, you’d also lose the use of your wipers. Beyond this, a lot more could go wrong with a hydraulic wiper motor over the years. They were reliable enough in use, but still far more complicated and with many more seals and gaskets compared to a simple electric wiper motor.

The wiper motor also usually featured a small filter for the power steering fluid. If this became clogged, it could hamper the performance of the steering and wipers alike. This could go unnoticed, as few owners were regularly thinking along the lines of “hey, I really should check my wiper motor fluid filter this fall.”

Even on this beat-up old 1968 Ford Thunderbird, the hydraulic wipers are powerful and fast.

GMC used hydraulic wipers on some motorhomes in the mid-1970s.

There is also one minor use case in which hydraulic wipers are inferior to the electric type. If your engine isn’t running, you can’t use the wipers. With the engine off, the power steering pump isn’t running, so there’s no hydraulic pressure to move the wipers. If you’re sitting in your parked vehicle and you suddenly need to see through the windscreen on a rainy day, you’ll need to start the engine.

The wipers used a small hydraulic motor that was attached via hydraulic lines to the power steering pump and the steering box. The lines were routed via a dashboard mounted control that could vary the speed of the wipers as desired. The technology used by Ford was referred to as Hydro-Wipe, and was developed by a supplier named Trico. In a beautiful nod to journalists of the future, the company was kind enough to emboss the relevant patent numbers for the technology right on the wiper motor castings.

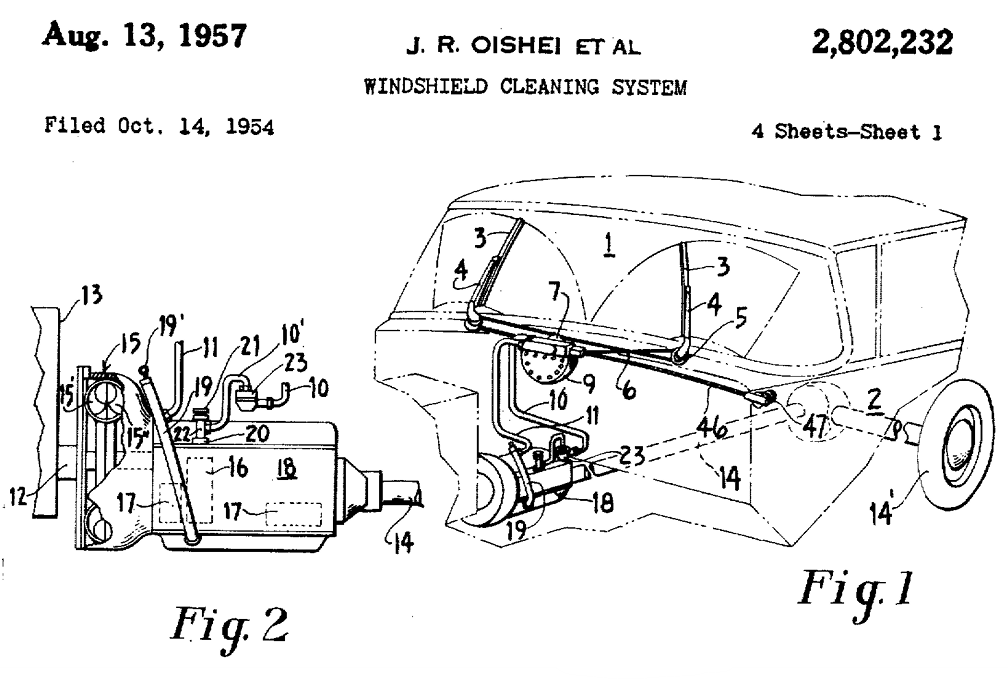

Trico filed several patents from 1954 to 1963 regarding the design of its hydraulic wiper systems. A particularly early filing suggested using hydraulic pressure generated by an automatic transmission. A later patent considered running a secondary pump using engine oil to provide power to the wipers.

It was only in later filings from 1959 onwards that Trico settled on using the power steering pump to provide hydraulic power for the wipers. This allowed for a less invasive install that didn’t risk damage to the automatic transmission or engine if there was a leak or something else went wrong.

Diagram from Trico’s patent, regarding the combined reciprocating hydraulic motor and speed-control metering valve. Credit: USPTO

The hydraulic motors used in Trico’s wiper mechanism were not a typical continuous rotation type. Instead, they featured a complicated reciprocating mechanism that saw fluid passed to either side of a vane as it turned back and forth through 180 degrees. Paired with the appropriate wiper linkages, this mechanism allowed for the predictable back-and-forth motion desired for wiping a windscreen.

Built into the base of the motors was a cable-controlled hydraulic metering mechanism. A control in the cabin tugged on the cable, which adjusted the hydraulic pressure reaching the motor via an in-built piston-type valve. The greater the pressure sent to the motor, the faster the wipers would move.

The hydraulic motor was a sizeable unit that lived under the windshield cowling.

Ford eventually abandoned hydraulic wiper motors, with the technology effectively disappearing from the lineup in the early 1970s. The Blue Oval largely went to electric wipers and didn’t look back. Notably, Trico found another customer, with some GMC motorhomes in the picking up hydraulic wipers in the mid-1970s.

Some classic Fords and Lincolns still get around with hydraulic wipers today. If properly maintained, the wipers still do the job—and with better performance than Ford’s earlier vacuum-powered wipers, too. However, there are options for those that tire of the complicated hydraulic setup. It’s possible to buy kits to convert these older vehicles to use a more typical electric wiper motor instead.

It’s not exactly clear why Ford went the hydraulic route in the 1960s. While it was an obvious upgrade over weaker vacuum systems, electric wipers were becoming fairly well established in this time period. At the same time, engineers back then weren’t so afraid of a little mechanical complexity. The internal combustion engine was still a marvel, less than a century old, and so were automobiles that could fling themselves down highways at triple-digit speeds. Ford engineers likely decided the wipers could have a little additional hydraulic circuit, as a treat.

Regardless, in this modern world, such oily, mechanical contrivances are very much a thing of the past. No serious automaker would consider running expensive high-pressure hydraulic lines where a couple of cheap wires would do. Similarly, electric motor technology is so advanced, and economies of scale so established, that prices are rock bottom for electromechanical devices. No complex hydraulic motor with many delicate moving parts could ever hope to compete. Hydraulic windscreen wipers will remain a curio of the 1960s, just one that isn’t as well remembered as the Apollo program, the Grateful Dead, or the San Francisco acid tests. Perhaps, a shame!

Image credits: Ford, US Patent Office, eBay

Whoa, these are cool…yeah, don’t forget to also check your horn and blinker fluid!

“Hydro-Wipe”

So is that also what a bidet is called?

Here’s an idea: use a hydraulic pump to run all the accessory equipment. It’s quiet, powerful, reliable, and you can automate everything from Windows to seat back position!

… Said a German engineer. Once.

Just imagine a Grosser-style T-bird. German engineering, late ’70s Ford reliability.

I have these hydraulic wipers in my ’66 T-bird! They work fantastically well, the car has never been restored and to my knowledge the wipers never had hydraulic issues.

The hydraulic wipers are a joy to use because the continuously variable wiping speeds enable you to set the wipers to the beat of the music you’re listening to, synchronized musical windshield wiping! Only for hydraulic wipers does the simplest variable speed control solution allow this… Which is the only reason why I can imagine electric wipers aren’t designed to do the same. Y’all are missing out on the joy of complete wiper speed control, I’m telling ya. 🙂

The only time my wipers ever broke was when some doofus tried to hammer the windshield wipers onto the spindles, breaking an aluminum spindle mounting bracket in the process, which I had to fix with JB weld because nobody makes a replacement for that part because you’d have to be an idiot to somehow break it, but I digress… At least having to fix the wiper mechanism gave me a chance to see the hydraulic wiper motor, it’s pretty neat.

Also, the Ford power steering pumps these hydraulic wipers ran off of used ATF as the hydraulic fluid, and will puke some of that fluid out if you turn the steering wheel too much without the engine running. I learned this from experience when my crappy Chinese alternator and voltage regulator crapped out and I had to push the car a few blocks to find a parking space to wait for a tow truck, and the tow truck driver was confused why ATF was leaking from the front of a RWD car onto his truck… Fortunately, that was the only time I ever had to have the car towed, and the fix was quick, simple, and inexpensive. The car is mechanically very reliable despite its age. Electrically however… let’s just say that’s another reason I’m glad the wipers are hydraulic 😉

I’m going to ask the stupid question:

Why would Ford change from the 2 speed electric wipers of 1962 to Hydro-Wipe for the last model year of the BulletBird? Why not just wait ’til the all new T-Birds of 1964?

I’m sure they made some process engineers at the assembly plant enemies for life. One more messy system to install, fill, and bleed on the line at one a minute or whatever rate they ran.

But is the engine at risk of blowing when the wipers are turned on like the Lancia Gamma and it’s power steering system?

This makes no sense to me.. Except as a case study in what happens when you’re the project manager of the wiper division at Ford and your deadbeat bother in law just got a “last chance” sales job at Trico..

My diesel truck has a hydraulic brake booster that runs off the power steering pump. It’s slower to respond than a vacuum booster, and in a 7000 pound vehicle, you have to plan ahead when it’s time to stop. It’s a huge mess of pipes and hoses between the components and I dread having to work on it.

Yours must need some maintenance then, my hydro boost works just fine in my truck, other ones I’ve driven felt fine too then. Honestly with the amount of diesel trucks using them they are pretty reliable

With a half million miles on it, I wouldn’t be surprised if it’s a little worn. It’s not super slow, it’s just not as quick as a vacuum booster.

Ah, makes sense. Half a million means you know how to maintain! Keep her trucking

I remember my brother bought a 67 Lincoln Continental convertible with those hydraulic wipers.

Just the switch seemed like an engineering nightmare with hydraulics, electrics and mechanical all crammed into one.

There’s a kit to convert the GMC Motorhome to use Chevy Lumina electric wipers. You get an intermittent setting that way.

Did the grosser 600 Mercedes use hydraulic for wipers too ?

I think that was one of the few things that weren’t hydraulic as I never saw it included in the list of hydraulic operations, but I could be wrong.

I owned a 64 T-Bird back in the late 80’s and let me tell you those suckers are complicated.

Hydraulic wipers, vacuum door locks and vents, unit body, swing away wheel etc. Ford really went to near-German levels of complexity in this era, particularly with Lincolns.

I am still surprised this 64-67 era of T-Bird has never really taken off in value. They drive like a sled and look amazing, especially inside.

I get Hagerty’s amazing car magazine, and in one issue last year IIRC they mentioned the 64-66 T-birds have recently started to go up in value. I believe it, as when mine got rear-ended in 2023, the insurance payout was almost three times more than I paid for the car in 2017, enough to both keep the T-bird and buy the Miata I’m driving now.

I blame muscle car mania for T-bird values remaining affordable. They’ve got plenty of power, but send it through a 3-speed auto and tall rear end gearing for a 0-60 of 11 seconds with the 390 or 9 seconds with the 428, making them respectable performers in their day but not appealing to the classic muscle crowd today. They were designed to be fast when passing on the highway, not making drag strip passes, and that’s why they’re still relatively cheap. I think now that every classic car is considered slow, more people are noticing 4th-gen T-birds as appealing classic cars with beautiful styling, cool fancy features, and plenty of power for a bargain price, so demand is going up.

I did love taking my T-bird to car shows as I could park it next to cars that cost four times as much and it didn’t look out of place 🙂 Even got lots of compliments as it was frequently the only 4th-gen T-bird there, so it felt unique.

I also am fortunate to have a base model, no vacuum door locks or the control panel in the ceiling like most T-birds of the era, not even air conditioning which is actually super rare for these cars not to have. The only vacuum lines in mine go to the rear window vent, which the large rubber hoses rotted away on so it doesn’t work anyway. The car’s still frigging complicated though, bought it thinking classics are supposed to be easy to fix but nooooope! Not this one! These were clearly designed to be fixed by the Ford dealership, not in your garage. I’m just glad mine is as simple as these cars get.

For a car of the era there’s remarkably little room to work on the engine. It’s a bear to work on.

Around the same time Ford used vacuum to power the central door locks and rear vents.

Helped a friend troubleshoot the vacuum everything in his tbird. What a nightmare that summer was.

My friend had to have new hydraulic hoses made for his 66. Fortunately, he squirreled out on most of the vacuum, and even managed to find a NOS center tail light section and a working turn signal sequencer (a motor operating three contacts in what was basically a heavily insulated coffee can).

Hydro-Wipe.

Huh-huh.

Huh-huh-huh.

huh-huh-huh-huh.

What I was thinking.

Damn – I was going to go with that bidet comment!

BRB going to see if Hydro-Wipe is trademarked and possibly start a bidet company

Are you quite sure you understand the readership?

As for hydraulic wipers, I will say from my time spent with a ’65 Thunderbird that they are significantly quieter than their contemporary electric counterparts which may be the main reason Ford used them on its fancier offerings.

You want to see a weird wiper set-up? It’s a triple, but not like the FJ or an MG Midget. No. It’s far stranger than that.

Check this out… at about the 5:00 into the clip.

https://youtu.be/4ywGZURUpKE