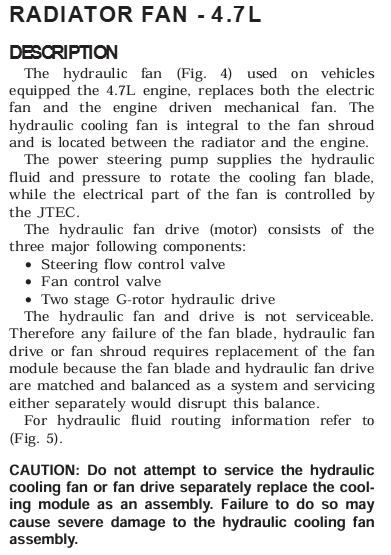

If you wanted to find a car with an oddball cooling system, where would you look? Perhaps you’d turn to Saab as purveyors of the unconventional, or maybe Lancia given their strange Italian ways. But what if I told you that it was Jeep that went the complicated, mechanically-contrived route?

If you’re running a vehicle with a combustion engine, it’s got a cooling system. That cooling system most certainly includes a fan. Its primary role is to draw air over the radiator (or fins, if it’s an air-cooled car). This way, your vehicle doesn’t overheat when towing or when you’re idling at a traffic light or running the air conditioner while you’re scarfing down chalupas in the parking lot of Wawa.

Historically, automakers used to run cooling fans right off the crankshaft-driven accessory drive (the fan would often be bolted to the water pump pulley). Later on, the electric fan rose to prominence for the sake of packaging, convenience. and efficiency. Only… there came a strange third solution. When Jeep looked for a way to cool its biggest, hottest engine, it got creative. What if the cooling fan could run off the power steering system?

Hydra-What Now!?

In 1999, the new “WJ” generation Jeep Grand Cherokee debuted. You could get it with a 4.0-liter straight six, or if you loved spending even more on fuel, the hefty 4.7-liter V8. The latter offered 235 horsepower and 295 pound-feet of torque — down a bit from the 1998-only 5.9 in the Grand Cherokee ZJ predecessor, but up from the more common 5.2-liter that had been in Grand Cherokees since the first model year of 1993.

When it debuted, the 4.7-liter PowerTech V8 was a step forward for Chrysler, being a single overhead-cam engine compared to the older pushrod designs used in the outgoing Grand Cherokee. It even made it on to the Ward’s 10 Best Engines list in 1999.

Soon enough, though, that engine would receive a rather fancy upgrade. Automotive supplier Valeo had come up with an idea—a hydraulic-powered cooling fan that could theoretically outperform the best crankshaft-driven and electric-driven fans on the market. As the company told the press at the time, the new hydraulic fans promised better fuel economy, better performance, and better packaging.

“Our system is much quieter and more efficient than traditional fans that connect directly to the engine through a clutch,” said Valeo’s James Neville, then general manager of the Air Flow Division. “Vehicles with engine-driven fans lack the refined aerodynamic features we see in passenger cars that use electric fans,” he explained. “But electric fans are seldom an option in trucks because their low air flow hampers towing capacity, under-hood cooling and air conditioning performance.” This, he implied, restricts aerodynamic design in trucks and SUVs. The solution was a high-powered hydraulic fan that could offer great cooling without the compromises of a crankshaft-driven unit [Ed Note: One compromise other than packaging/design was that with mechanical fans, fan speed is connected to engine speed; sometimes you actually want to run your fan more slowly than your engine, and while hydraulic fan clutches on accessory drive-driven fans are a thing, they’re not that efficient. -DT].

Of course, building a special hydraulic pump to run off the engine would cost a lot. It would be a lot of fuss to go to just for a cooling fan. But this was Valeo’s special sauce—it realized that modern automobiles already had a high-pressure hydraulic pump on hand—it was there to run the power steering! The company’s engineers realized that they could use a single pump to run the steering and the cooling fan, keeping the system’s complexity to a minimum.

Valeo claimed its setup could flow 20 to 30 times as much air as a typical electric fan of the era. In particular, it noted that its system could provide higher airflow at idle and low speeds, and was particularly useful under high-load conditions such as heavy towing. The system was also configured to prioritize steering operation over the cooling fan in brief periods where both systems called for high power. Jeep noted the serious efficiency benefits, too. “The HDFS reduces the consumption of horsepower as compared to current engine-driven fan cooling systems—[by] up to 19 horsepower—and returns that power to the rear wheels,” said Steve Johnston, then in charge of of Jeep’s cooling systems.

Hydraulic-powered fans might seem like an odd solution to cooling an engine. They’re a lot more mechanically complicated than simply throwing a fan on a crankshaft-driven water pump, or wiring up an electric fan to do the job. In comparison, hydraulic fan systems have many more moving parts, and require additional fluid lines and fittings. It’s basically just something else that can leak on your vehicle.

Today’s automobiles have can easily deliver a ton of juice to a powerful, compact, efficient electric motor (which can switch on and off based on cooling needs, saving power over constantly-spinning crankshaft-driven fans). But twenty to thirty years ago, that wasn’t so much the case. Electric motors were larger and less powerful, and automotive electrical systems weren’t kitted up to deliver so much juice. Back then, if you needed a powerful fan to cool a big hot V8 engine, you could do it much more easily with a hydraulic power steering pump driven right off the engine. This could deliver plenty of power to a small dual-displacement (i.e. two-speed) hydraulic motor turning a fan on the back of the radiator (see above).

Hydraulic fans don’t miss out on controllability, either. Jeep used solenoid valves to control the flow of hydraulic fluid in their fan systems, which would effectively allow the fan speed at the appropriate speed and shut off as needed. This offers significant efficiency benefits, which — along with the airflow capabilities — made this this HDFS so appealing.

As highlighted by Dande_In_The_Garage, any leak or failure in the power steering system compromises the engine’s ability to cool itself.

Ultimately, the benefits of Valeo’s fans to the customer weren’t necessarily as huge as they sounded. The Jeep Grand Cherokee didn’t gain any real boost to its EPA fuel economy ratings after the hydraulic fans were implemented. Nor did the Grand Cherokee gain a big lift to its maximum towing capacity. While the hydraulic fan had its plus points, it wasn’t a big gamechanger in most customers’ eyes, and as the fans needed service, they were considered by some a burden.

As seen in the video below, many owners have chosen to later convert their hydraulic fan-equipped models to electric fans for simplicity. And eventually, Jeep dumped hydraulic cooling fans when it started building the fourth-generation Grand Cherokee in 2011.

Other Users

The innovative solution spread from Jeep to its sibling brands as well. As Wards notes, in 2003, it was picked up for the 8.3-liter V10 engine in the new third-generation Dodge Viper. Just like the Jeep units before, the new setup was supplied by Valeo, and this setup was used in the Dodge Ram SRT-10 (which shares the Viper’s engine), too.

It wasn’t just the DaimlerChrysler brands that were tinkering in this area, however. Toyota liked to use hydraulic cooling fans, too, and they’d been at it since the early 1990s. The most notable use case was the 4.0-liter 1UZ-FE V8 engine, as seen in the Toyota Soarer and the Lexus LS400.

However, rather than using the power steering pump to provide hydraulic pressure for the radiator fan, Toyota had decided to install a dedicated pump on the engine just for this purpose. The hydraulic pump sits on the front of the engine, and is turned by the accessory belt. It was less elegant than the Valeo solution, but it did the job.

The reservoir for the hydraulic oil sits on the radiator fan assembly itself. Amusingly, the cap reads “ENGINE FAN FLUID,” but that’s referring to the fluid’s purpose, not its type. The hydraulic fan system uses automatic transmission fluid, readily available off the shelf at any auto parts store.

Picked up a Toyota Celsior, checking fluids and filters, and came across this. Before today I would have laughed at anyone filling up on fan fluid.

byu/Kursawow inJustrolledintotheshop

Ford also implemented hydraulic cooling fans, most notably on the 2000 to 2002 Lincoln LS and the 2002 Ford Thunderbird. Like Toyota, Ford used a special pump for running the cooling fan, as opposed to the DaimlerChrysler solution of using the hydraulic output of the power steering pump. Similarly to Toyota, Ford’s system used ATF as its hydraulic working fluid.

However, Ford didn’t stick with the hydraulic fans for very long. The Ford Thunderbird would switch to electric fans for 2003 onwards, as would the Lincoln LS. In the latter case, the LS received a revised alternator with its 2003 refresh. Its greater output enabled Ford to switch to a simpler electric fan setup.

One can imagine a shocked owner yelling at a mechanic for trying to sell them a “fan fluid change,” but it’s a real thing. Credit: Ford

One can imagine a shocked owner yelling at a mechanic for trying to sell them a “fan fluid change,” but it’s a real thing. Credit: Ford

It’s easy enough to understand why automakers explored the use of hydraulic cooling fans. They promised better cooling performance than electric fans and more convenience/efficiency than traditional crankshaft-driven fans (with packaging/”styling-freedom” being part of that convenience). It’s also easy to see why they didn’t stick around. They were mechanically complicated (with more failure modes, like leakage) and more expensive to produce and not as efficient as electric fans.

Not every new automotive technology gets to stick around forever. Ultimately, hydraulic fans were fussy enough that automakers saw fit to dispose of them after only a decade or so in the limelight. Still, if you buy yourself an old Grand Cherokee or rusty Toyota Soarer, you might just find this oddball solution keeping your coolant from boiling over.

Image credits: Jeep, Ford, Toyota, eBay, Dande_In_The_Garage via Instagram screenshot

Dammit, I wish I never read this now. Now I have one more fucking thing to worry about with my 250.000 mile Grand Cherokee.

For what it’s worth, in the two pictures/short texts from the manuals, I spotted two mistakes. One is a simple missing comma or something, but labeling two things as 5 on the cooling system diagram is surprising.

These might have caught on had they been introduced earlier. Electric power steering was already starting to be a thing around this time.

Where is this mythical Wawa that sells chalupas located Lewin? I mean their hoagies are top notch, but I’ve never seen chalupas. I always figured that to be a GetGo kinda food offering.

My first question as well. They may have tested a Chalupa but it didn’t make the permanent menu. Maybe it was a Wawa with a Taco Bell next door?

I first learned of this when I went to help my friend repair her Grand Cherokee’s leaking power steering. She and I could not fathom why her vehicle would overheat with a full reservoir of coolant, new thermostat, water pump, etc. It was overheating when the power steering reservoir would get low, so mI started to trace the power steering lines and realized that they were connected to the cooling fan. It took the noggin a few minutes to reboot after thinking, “what magic is this?!”. Sadly, OEM hoses are no longer available, but we found a local place that would make new hoses (if you provided the old hose as a template). Also sadly, that shop closed up when the owner retired.

This traumatizingly brought me back to discovering, learning , understanding, diagnosing and replacing this pieceashit set up and its various hydraulic hoses on a customer’s 05 Viper SRT10. Like, what the actual fuck. This was during COVID when parts were at a premium. Took 3 months to get one in.

Hey, it was a tidy payday at least.

Hydraulic cooling fans have been common in the bus industry for a while, as before electric fan tech was capable of providing adequate cooling, hydraulic power allowed more flexible packaging and positioning of the cooling module.

The most memorable application was on some British engineered units we had about 13 years ago.

The radiator was cooled by an electric fan assembly. That system itself was so horribly designed and built that there should have been a lawsuit, but I digress.

The intercooler was cooled by a hydraulic fan with it’s own pump. They decided to mount the pump right onto the front of the crank shaft. The only thing preventing the pump from twirling along as the engine turned were the hydraulic lines connected to it. So the 2 braided lines were tasked with counteracting the 30 or more horsepower that it takes to run the pump, as well as absorbing the pulses generated.

The outcome was that the nose of the pump would break off, and the pump would come to rest on the crank pulley.

Usually it would sit there for a while, as it would only cause a temporary check engine light under severe conditions, so I had to make a habit of wiggling the pump to see if it’s actually attached to anything.

100% failure rate.

I ran to the comments to mention how they’re used extensively on bus applications!

I’m happy to say that they are being phased out. Good riddance!

Genuinely didn’t know about this one. The WJ was therefor peak hydraulic. You could get one with a hydraulic fan, hydraulic front and rear differentials and a hydraulic center coupling (quadra-drive with vari-lok). Including the power steering and transmission…there were a lot of little hydraulic circuits on that sucker.

I learned of this when I was assisting a friend of mine with her Grand Cherokee. It immediately made me think of older cars that ran the power steering pump off of the back of the generator. “Intermittent power steering assist AND poor charging ability? Where do I sign?”

This is pretty interesting but I don’t believe for a minute that electric fans were somehow not up to the task. I modified a ‘76 F250 about 30 years ago and installed two generic electric fans on the back side of the radiator and deleted the original fan. Mine were simply controlled by toggle switches on the dash. I used the truck to tow a ski boat and while I was taking my sweet time launching or retrieving the boat at the ramp, I could turn on one fan and adequately ventilate the engine compartment a lot more efficiently that the original engine driven fan, which would have been turning slowly at idle. If the truck was moving at any speed I simply turned them off since they weren’t needed. The whole point of having them was to improve air flow through the engine compartment while the truck was stationary. One fan turned out to be more than enough even in +100 degree weather.

Ohh im sure they had adequate fans for the time, ones thatd work on any given generic v8 vehicle, but where the decision likely stood was cost per unit, implementation cost, possibly warranty, but lastly id say would be packaging

The electric draw with older alternators pushing the amp demand then voltage was quite a bit.

Most stuff in the 90s were only 85 amps or so, so a pair of big ol fans would be a good whack to an electric system in cars.

I enjoyed this article. I have a 2010 Jeep Commander with the 5.7 hemi that has this system. I have owned the vehicle for over 10 years and 150,000 miles and have never had a real issue with it. I know a few other owners of Jeep Commanders and honestly I think it is a reliable system — we never complain about it. I do change the power steering fluid periodically (it is just ATF-4 that is a different color), and once replaced one of the lines because it was leaking. Now, what is interesting is that I also have a 2000 Dodge Durango with the 4.7 Powertech engine, and it does not have this system despite sharing this engine with the Jeep Grand Cherokee, It has both a fluid clutch fan that runs off of the engine (so robbing some horsepower) and also an electrical fan.

You know i was wondering what the engine fan fluid was on my 96 Aristo (1st gen Lexus GS)

Tatra did this on their air cooled gasoline V8s and their diesel V12s – but used the engine oil pressure itself. Allowed for fast warm-ups in really cold conditions and operation of the diesel with a busted belt.

Fan speed was thermostatically controlled via a mechanical valve.