If you wanted to find a car with an oddball cooling system, where would you look? Perhaps you’d turn to Saab as purveyors of the unconventional, or maybe Lancia given their strange Italian ways. But what if I told you that it was Jeep that went the complicated, mechanically-contrived route?

If you’re running a vehicle with a combustion engine, it’s got a cooling system. That cooling system most certainly includes a fan. Its primary role is to draw air over the radiator (or fins, if it’s an air-cooled car). This way, your vehicle doesn’t overheat when towing or when you’re idling at a traffic light or running the air conditioner while you’re scarfing down chalupas in the parking lot of Wawa.

Historically, automakers used to run cooling fans right off the crankshaft-driven accessory drive (the fan would often be bolted to the water pump pulley). Later on, the electric fan rose to prominence for the sake of packaging, convenience. and efficiency. Only… there came a strange third solution. When Jeep looked for a way to cool its biggest, hottest engine, it got creative. What if the cooling fan could run off the power steering system?

Hydra-What Now!?

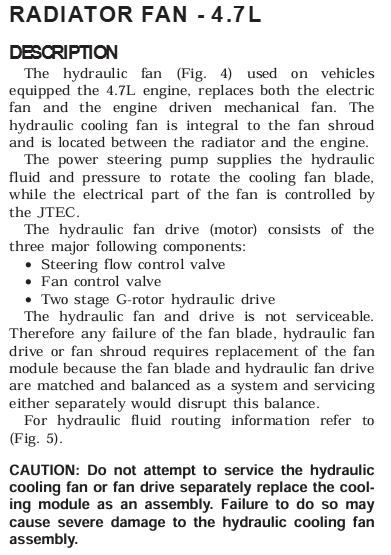

In 1999, the new “WJ” generation Jeep Grand Cherokee debuted. You could get it with a 4.0-liter straight six, or if you loved spending even more on fuel, the hefty 4.7-liter V8. The latter offered 235 horsepower and 295 pound-feet of torque — down a bit from the 1998-only 5.9 in the Grand Cherokee ZJ predecessor, but up from the more common 5.2-liter that had been in Grand Cherokees since the first model year of 1993.

When it debuted, the 4.7-liter PowerTech V8 was a step forward for Chrysler, being a single overhead-cam engine compared to the older pushrod designs used in the outgoing Grand Cherokee. It even made it on to the Ward’s 10 Best Engines list in 1999.

Soon enough, though, that engine would receive a rather fancy upgrade. Automotive supplier Valeo had come up with an idea—a hydraulic-powered cooling fan that could theoretically outperform the best crankshaft-driven and electric-driven fans on the market. As the company told the press at the time, the new hydraulic fans promised better fuel economy, better performance, and better packaging.

“Our system is much quieter and more efficient than traditional fans that connect directly to the engine through a clutch,” said Valeo’s James Neville, then general manager of the Air Flow Division. “Vehicles with engine-driven fans lack the refined aerodynamic features we see in passenger cars that use electric fans,” he explained. “But electric fans are seldom an option in trucks because their low air flow hampers towing capacity, under-hood cooling and air conditioning performance.” This, he implied, restricts aerodynamic design in trucks and SUVs. The solution was a high-powered hydraulic fan that could offer great cooling without the compromises of a crankshaft-driven unit [Ed Note: One compromise other than packaging/design was that with mechanical fans, fan speed is connected to engine speed; sometimes you actually want to run your fan more slowly than your engine, and while hydraulic fan clutches on accessory drive-driven fans are a thing, they’re not that efficient. -DT].

Of course, building a special hydraulic pump to run off the engine would cost a lot. It would be a lot of fuss to go to just for a cooling fan. But this was Valeo’s special sauce—it realized that modern automobiles already had a high-pressure hydraulic pump on hand—it was there to run the power steering! The company’s engineers realized that they could use a single pump to run the steering and the cooling fan, keeping the system’s complexity to a minimum.

Valeo claimed its setup could flow 20 to 30 times as much air as a typical electric fan of the era. In particular, it noted that its system could provide higher airflow at idle and low speeds, and was particularly useful under high-load conditions such as heavy towing. The system was also configured to prioritize steering operation over the cooling fan in brief periods where both systems called for high power. Jeep noted the serious efficiency benefits, too. “The HDFS reduces the consumption of horsepower as compared to current engine-driven fan cooling systems—[by] up to 19 horsepower—and returns that power to the rear wheels,” said Steve Johnston, then in charge of of Jeep’s cooling systems.

Hydraulic-powered fans might seem like an odd solution to cooling an engine. They’re a lot more mechanically complicated than simply throwing a fan on a crankshaft-driven water pump, or wiring up an electric fan to do the job. In comparison, hydraulic fan systems have many more moving parts, and require additional fluid lines and fittings. It’s basically just something else that can leak on your vehicle.

Today’s automobiles have can easily deliver a ton of juice to a powerful, compact, efficient electric motor (which can switch on and off based on cooling needs, saving power over constantly-spinning crankshaft-driven fans). But twenty to thirty years ago, that wasn’t so much the case. Electric motors were larger and less powerful, and automotive electrical systems weren’t kitted up to deliver so much juice. Back then, if you needed a powerful fan to cool a big hot V8 engine, you could do it much more easily with a hydraulic power steering pump driven right off the engine. This could deliver plenty of power to a small dual-displacement (i.e. two-speed) hydraulic motor turning a fan on the back of the radiator (see above).

Hydraulic fans don’t miss out on controllability, either. Jeep used solenoid valves to control the flow of hydraulic fluid in their fan systems, which would effectively allow the fan speed at the appropriate speed and shut off as needed. This offers significant efficiency benefits, which — along with the airflow capabilities — made this this HDFS so appealing.

As highlighted by Dande_In_The_Garage, any leak or failure in the power steering system compromises the engine’s ability to cool itself.

Ultimately, the benefits of Valeo’s fans to the customer weren’t necessarily as huge as they sounded. The Jeep Grand Cherokee didn’t gain any real boost to its EPA fuel economy ratings after the hydraulic fans were implemented. Nor did the Grand Cherokee gain a big lift to its maximum towing capacity. While the hydraulic fan had its plus points, it wasn’t a big gamechanger in most customers’ eyes, and as the fans needed service, they were considered by some a burden.

As seen in the video below, many owners have chosen to later convert their hydraulic fan-equipped models to electric fans for simplicity. And eventually, Jeep dumped hydraulic cooling fans when it started building the fourth-generation Grand Cherokee in 2011.

Other Users

The innovative solution spread from Jeep to its sibling brands as well. As Wards notes, in 2003, it was picked up for the 8.3-liter V10 engine in the new third-generation Dodge Viper. Just like the Jeep units before, the new setup was supplied by Valeo, and this setup was used in the Dodge Ram SRT-10 (which shares the Viper’s engine), too.

It wasn’t just the DaimlerChrysler brands that were tinkering in this area, however. Toyota liked to use hydraulic cooling fans, too, and they’d been at it since the early 1990s. The most notable use case was the 4.0-liter 1UZ-FE V8 engine, as seen in the Toyota Soarer and the Lexus LS400.

However, rather than using the power steering pump to provide hydraulic pressure for the radiator fan, Toyota had decided to install a dedicated pump on the engine just for this purpose. The hydraulic pump sits on the front of the engine, and is turned by the accessory belt. It was less elegant than the Valeo solution, but it did the job.

The reservoir for the hydraulic oil sits on the radiator fan assembly itself. Amusingly, the cap reads “ENGINE FAN FLUID,” but that’s referring to the fluid’s purpose, not its type. The hydraulic fan system uses automatic transmission fluid, readily available off the shelf at any auto parts store.

Picked up a Toyota Celsior, checking fluids and filters, and came across this. Before today I would have laughed at anyone filling up on fan fluid.

byu/Kursawow inJustrolledintotheshop

Ford also implemented hydraulic cooling fans, most notably on the 2000 to 2002 Lincoln LS and the 2002 Ford Thunderbird. Like Toyota, Ford used a special pump for running the cooling fan, as opposed to the DaimlerChrysler solution of using the hydraulic output of the power steering pump. Similarly to Toyota, Ford’s system used ATF as its hydraulic working fluid.

However, Ford didn’t stick with the hydraulic fans for very long. The Ford Thunderbird would switch to electric fans for 2003 onwards, as would the Lincoln LS. In the latter case, the LS received a revised alternator with its 2003 refresh. Its greater output enabled Ford to switch to a simpler electric fan setup.

One can imagine a shocked owner yelling at a mechanic for trying to sell them a “fan fluid change,” but it’s a real thing. Credit: Ford

One can imagine a shocked owner yelling at a mechanic for trying to sell them a “fan fluid change,” but it’s a real thing. Credit: Ford

It’s easy enough to understand why automakers explored the use of hydraulic cooling fans. They promised better cooling performance than electric fans and more convenience/efficiency than traditional crankshaft-driven fans (with packaging/”styling-freedom” being part of that convenience). It’s also easy to see why they didn’t stick around. They were mechanically complicated (with more failure modes, like leakage) and more expensive to produce and not as efficient as electric fans.

Not every new automotive technology gets to stick around forever. Ultimately, hydraulic fans were fussy enough that automakers saw fit to dispose of them after only a decade or so in the limelight. Still, if you buy yourself an old Grand Cherokee or rusty Toyota Soarer, you might just find this oddball solution keeping your coolant from boiling over.

Image credits: Jeep, Ford, Toyota, eBay, Dande_In_The_Garage via Instagram screenshot

I learned something new today. Thanks Autopian!

It’s really interesting to find niche engineering within in-between tech eras. Obviously electrification is the modern answer with improved controller technology and manufacturing advances. I’m especially curious to speculate on our current “niche” solutions that will not withstand the march of time.

Nissan got into the game, too. The President/Infiniti Q45 and first generation M45 had a hydraulic fan motor similar to the Toyota system with a separate pump.

When the hydraulic fan system on the Jeep was new, we were told that the fan would always spin any time the engine was running, but that it wasn’t being spun with significant force unless the control solenoid was ON. This was due to a minimum flow through the system. Like a dumbass, I put my thumb up against the outer ring (on the fan blades) and stopped the fan while the engine was running at a cold idle. I was rewarded with a mildly cut thumb. OOPS.

I’m not a fan. Can’t really get pumped up about this one.

See what you did there.

Mile Marker winches also used the power steering pump in applications where you couldn’t get a PTO driven pump.

Unless there’s some Australian Wawa I am not familiar with, if you’re eating a chalupa in the Wawa parking lot you brought it there yourself. Now a hoagie…

Damn it, I knew I’d trip on this. I was sure Wawa had chalupas!

Wawa has hoagies, pizza, hamburgers, hot dogs, burritos, quesadillas, pasta, salads, soup and probably some other stuff too. So chalupas was a reasonable assumption.

Two Decades Ago, Jeep Figured Out How To

Get The Power Steering Pump To Cool A V8 EngineMake a Fan LeakAlso an excellent headline.

This was a super common fan rive on equipment long before Jeep, or any other auto manufacturer, thought to put it in cars.

The fan motors are expensive but usually last WAY longer than electric ones.

Yes used on earthmovers from at least from the 1960s on.

A Lexus ES300 (96 with a V6) had the cooling fan run off the power steering pump. Changing that pump did not endear me to transverse V6 fwd cars

-from what I could find on a Lexus forum around mid-2000s, this was done for nvh purposes.

That seemed a fair bit of weight, complexity, and cost for what I can only project as a relatively minimal reduction in noise. You’re still a spinning a fan.

I learn many things from the articles, but am constantly amazed by the knowledge of the readership. I barely pass as an auto-enthusiast and would probably be thrown off the site, except for the fact that I’m a member. I guess I’m like Groucho and wouldn’t be a member of any club that would have me.

There’s no test beyond self-admitting to be into some aspect of cars:

‘You like?’

Well, yeah’

‘Welcome aboard!’

Thank you!

I’ve had imposter syndrome my whole life. Just cause I can’t identify a top-loader from a rock-crusher transmission by glancing at them doesn’t mean I’m not competent at certain things—nor does it prevent me from enjoying my drives. Screw the gatekeepers (especially if they be internal!), and go enjoy your ride!

DRIVE THAT SHIT 🙂

While not funny, this is my COTD because it sums up my feelings about this site pretty well.

Happy to know that I’m not the only one.

Should have combined it with hyrdoboost brakes to make it even more complicated or simpler depending

I was gonna throw Hydroboost brakes into the mix, but those really only make sense for vehicles (like Diesels) that don’t make much/any vacuum on their own.

I admire Valeo for thinking outside the box on this. Like a whole bunch of new (for their era) automotive technologies, this seems like a great solution to the problem at hand… until it breaks, when it becomes an absolute nightmare.

Hydroboosts are good for cramped applications where there’s not room for a big booster, and they’re great for guy who put big cams in motors and the corresponding lack of vacuum. Although these days, an electric vacuum pump is an easier solution.

Yep, Hydroboost brakes used to be a thing for trucks with big-block V8s. At idle and low RPMs, vacuum would drop like a rock. So there needed to be an alternate way to provide it for brake boost. Larger trucks sometimes had a backup electric pump for safety which would at least partially pressurize the hydraulic system if the accessory belt to the power steering pump let go. Pressing the pedal down with the ignition on but the engine not started would make it run.

So they are saying the hydraulic pump would produce as much power as a 14k-watt electric motor? I mean, I know that the conversions are straightforward, and suppliers are like after-market folks with outrageous promises, but that one seems a bit over the top since even if it reduced power consumption by 80%, it would mean that the Jeep’s cooling fan would need to draw up to 24hp, 10% of engine output.

Hydraulic pump is a low-loss means to transfer power from one location to another and the hydraulic motor can produce monster torque, allowing it to turn large blades at low speeds. A mech fan does the same but has higher friction losses in the fan clutch. Electric fans are constrained by the practical motor size, both in physical space and available current from a practical alternator, so they rely on thinner, denser blades assemblies operating at higher speeds. In automotive applications e-fans always have difficulty matching performance of a fluid-coupled option at a given rotor diameter.

I understand. But the point is that to save 19hp, being even 80% more efficient would mean that a nonhydrolic fan would use 10% of the engine’s peak power output, which doesn’t seem realistic, especially since electric motors are typically 70-90% efficient. Something ain’t mathing.

Gosh, I was expecting to read a story about the time back when Renault owned Jeep, and perhaps a Citroen engineer played a practical joke on his friend, the Renault engineer by convincing him that hydraulic fans were the wave of the future.

Speaking of hydraulics where you wouldn’t expect them- Honda developed, and briefly sold, a big scooter (DN-01) that used hydraulic drive to the rear wheel. Engine powered a variable displacement swashplate style pump, lines ran to a motor on the rear wheel. It would either run in full-auto, or you could “shift” it with some paddles to lock it into discrete ratios.

So it was technically a CVT, but not the type you normally think of on scooters. Supposedly it worked just fine, and only needed very infrequent fluid changes (effectively “lifetime” fluid given how few miles most motorcycles accumulate), vs traditional CVTs need periodic belt replacement and cleaning.

One of those answers to a question nobody was really asking. It was technically better, but also much more expensive to manufacture, with no real tangible benefit to the end user.

Honda abandoned it and then came out with their motorcycle DCT option a couple years later instead.

It was sold as a motorcycle rather than a scooter. It was a weird thing that didn’t sell although I know a guy who is on his second one. At the time, dealers said that DN-01 stood for “Do Not Order One”

Mercedes should do a feature on it.

CVT? Lifetime fluid? Sounds like an Xtronic for Hondas.

Maybe they were onto something…

Also, like the fan, this is automotive stealing from the equipment side of things. That is just a hydrostatic drive. Same thing that has been moving every skid steer around for almost forever.

Honda, like Jeep in the WJ, also liked to use hydraulic pumps for 4wd. They both used geroter pump loops of hydraulic fluid to control 4wd coupling.

I have owned five jeeps. I’m glad that I never had to have the conversation with a repair person that said your fan is leaking. Part of the problem is you still had wires to the solenoids. This is almost as bad as electronically controlled carburetors in the worst of both possible worlds department. Imagine how drunk and or high the committee that OKed this was at the time.

“hey boss, we need to develop a higher power electric fan for the new Grand Cherokee”

**boss looks up from his desk with white powder still on his nose**: “Why not just make it hydraulic?!?!?!”

XJ and early GC’s cooling systems were constrained by styling. XJ Cherokees are famous for overheating any time the cooling system gets even slightly out of balance because of the short grill height. On the ZJ redesign that became the Grand Cherokee, they kept the short grill styling but filled the nose with radiator by adding a bottom breather intake. That produced a square radiator which could only accommodate a single fan, so it had to be a big one, and efficient.

Transit buses of the same era used hydraulic fans as well, until the power of electric fans and alternator output caught up to them.

We use a dedicated pump though, which is stacked on the back of the air compressor, with the power steering pump stacked on the back of that. (it’s not as bad as it sounds, takes about an hour to swap the pump on most ISL9 equipped buses).

My experience is that on vehicles/equipment for commercial usage, considerably more thought is given to serviceability and minimizing downtime for repairs.

Like when you go from a 3500 chevy, to the 4500, it’s suddenly in a totally different chassis/body where the entire front hood/fenders flips forward (and comes off in 5 minutes) to give total access to the engine. A job that requires pulling the diesel in a 3500 for access can be done just with flipping the hood up in a 4500.

Oh the access is utter dogshit for a lot of stuff on a transit bus. This just isn’t one of them. lol

I knew this sounded similar, and then I realized that the buses we work on also have these! These are relatively modern too, but I guess it’s still a worthwhile system. I didn’t have to do anything with this system yet, but I can confirm, access on buses can be extremely hard. Hatches in the floor of the passenger compartment, etc… tour buses/coaches too! You would think a big box on wheels would have plenty of space…

Even worse, on one of the generations of articulated buses we had (Icarus), The engine was on it’s side under the floor in the middle of the bus!

Well well well, I never would’ve thought you’d say Ikarus! If it’s the old Hungarian buses, I did my fair share of riding around in them in Hungary, where they were in use simultaneously with approximately 30 years newer Mercedes Citaro buses, as backup buses. I always thought it strange that those Ikarus’ had rear-axle steering, and thus middle-axle drive, unlike any other articulated buses. So the middle mounted engine does weirdly make sense. Even when I was 10 I was fascinated by them!

If you’re talking about an other bus, disregard the rant! 😉

OMG I’m glad my WJ had the 4.Slow.

Same here, especially considering that I have a leak in my power steering system that I really should address.

As a fluid power guy, I dig it. Hydraulic cooling fans are widely used on mobile equipment, but of course they have hydraulic systems to support them.

Wish they had a more detailed schematic so I could see what’s really going on in there.

Yup, Fendt tractors immediately come to mind with many of the larger models using hydraulic fans. Massey swathers use a hydraulic fan and Massey combines did for a short while in their V-cool system. While they are variable speed, the real benefit was the simplicity in being able to reverse the fan for clearing chaff over a variable pitch blade solution.

In retrospect it seems like this was only ever going to be an interim solution. Once electric fans got good enough to provide enough cooling for these engines they’re clearly the better option. Until then, the ability to have a controllable, high power fan might have justified the drawbacks.

And I suspect it’s incredibly difficult to predict something like improvement levels in electric fans over time with any amount of certainly, so that could be why these oddball choices are made. I’m not at all involved in automotive R&D so if more knowledgeable folks care to chime in, I’m very curious to hear it.

Toyota also used a power steering fan-powered hydraulic fan on the 3rd gen Camry when equipped with a V6, from 92-94 (he ES300 got it through 96)

If I recall right the Camry also used a two-stage power steering pump. One stage ran the fan and the other stage ran the power steering; all in one unit using shared fluid.

In 2009 or 10 I was part of an effort to figure out how to add a 2nd alternator to MRAP armored vehicles as the electronics load was outpacing the vehicle’s capabilities. There wasn’t room under the hood nor any more capacity in the 12 or 14 rib serpentine accessory drive belt to add a 27kw alternator, nor was there room to gear-drive one from the power take off on the transmission, but there WAS room to mount a hydraulic pump at the PTO. This allowed the alternator to be mounted wherever there was room with a hydraulic motor giving it the whirls. It was an interesting idea, but added a lot of failure modes and was not very efficient. And it needed a heat exchanger (with its own electric fan) added to keep the fluid from boiling which presented just another point of susceptibility that you didn’t really want on an armored vehicle.

This hydraulic fan solution was also done on the the V8 Lincoln LS, and the Retro-bird Ford Thunderbird from 2002-2005.

The real reason why? I asked an engineer that worked on the programs and the only reason why is because they ran out of room/bandwidth in the electrical architecture to run electric fans on these models. Not that it was impossible to do an electric fan, but that the cost to redo other electrical components of the car was more expensive vs just using the hydraulic fan solution.

I’m assuming the same was the case for the garbage 4.7 they put in the WJ

Yeah, I have to assume the issue wasn’t “we don’t have a motor big enough to power a bigger fan”, but rather “we don’t have the electrical capacity to power a bigger fan”.

Maybe an issue of alternator output at idle when the fan would typically draw a large load.

Kinda cool, overcomplicated, a bevy of failure modes and providing negligible benefit. This honestly screams German more than US or Japanese.

I was working at a shop when the first LS400s were out. We all gathered around as the hood was opened with the engine running. That engine made no sound whatsoever at idle. “Are we sure it’s running?”

It was like looking into the future.

It’s like the Mercedes W126 420SEL my parents had when I was young. That car was so smooth and quiet that it would freak passengers out thinking the car had stalled at intersections.

My friend has a minty 80s Toyota Celica Supra, a naturally aspirated one, and that engine is insanely quiet with the hood open.

The French love their hydraulics.

A friend of mine has a DS, I hear a lot about hydraulics every time that car comes up.

They truly do. I myself am a Claude-Louis Navier guy.

Want to buy a bridge?

The Navier-Stokes equations are CLASSIC.

vive le liquide