The Ford Mustang Mach-E is an important model for the Blue Oval. It might not be the showiest, fastest, or shiniest vehicle out there, but it’s helping the brand gain a foothold in the EV world. To that end, it’s been iterating on the design and making improvements, and Munro Live is here to show us those in greater detail—in particular, the new rear motor.

At Munro Live, our host for the teardown is Paul Turnbull. He’s laid out an older 2021 Mustang Mach-E motor on the bench, and put it next to a rear motor sourced from the Ford F-150 Lightning. Why? Because it’s functionally the same in-house built unit as Ford is now using in the Mustang Mach-E.

Ford is now claiming faster acceleration and better quarter-mile times for the 2024 model—something dearly demanded by performance-focused customers. The teardown gives us a nice insight into why the new motor is the hotter sauce, particularly for the drag strip.

The Change

The decision to switch up the Mustang Mach-E’s rear motor didn’t make a lot of headlines, though Design News was across it earlier this year. Basically, Ford wanted to abandon the unit it was sourcing from an external supplier, and instead kit the model out with something developed in house. Hence, it ended up with the Lightning motor.

But what of the older part? The Mach-E’s original rear motor was manufactured by Borg-Warner. The example seen here was sourced from Munro’s 2021 Mach-E teardown.

It’s worth noting that for this analysis, we’re not looking at the rear drive unit as a whole. Instead, Turnbull is showing us a comparison between the stators of the old and new motors. That’s enough to illustrate the primary differences between the two.

Before we go further, let’s have a quick interlude to define some terms that are relevant to these permanent magnet motors—and I’ll throw in some diagrams below! What’s a stator? Well, it’s the big metal part of the motor that is, as the name implies, stationary. A stator is typically made of laminated plates of special steel that reduces eddy current losses, and is the structure that holds the windings. The stator windings are basically coils of copper wire wrapped around the stator core to generate the rotating magnetic field that makes the motor spin. If you’ve ever wound a coil of wire around a nail to make an electromagnet, you’re familiar with the concept. Windings in EV motors tend to use more advanced geometries and thicker wires, but the concept is the same. Wrap a conductor around some metal, run some current through it, and you’re generating a magnetic field.

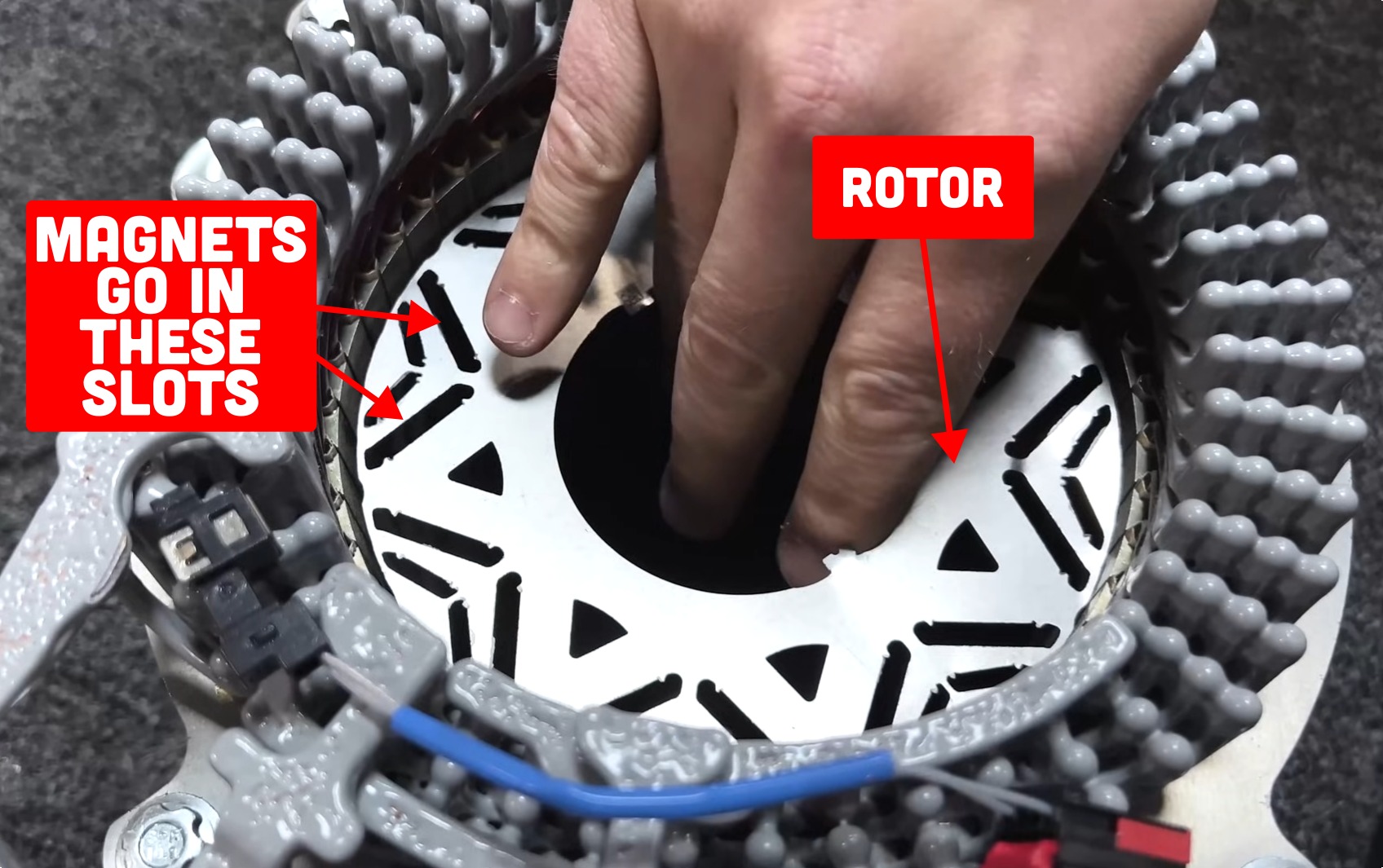

What we don’t see in this video is the rotor, which is the central spinning part of the motor. The rotor has permanent magnets on it, so when the changing currents in the windings create a rotating magnetic field, the rotor spins in turn. It’s the job of the motor’s control electronics to energize and de-energize the separate windings in the right sequence to make the rotor spin. There are usually three sets of windings, or “phases,” that have to be switched in the right order to make the motor turn.

Okay, so back to the motors. The most obvious change to the new unit? “In this case, though, Ford has decided to go with a winding that’s a little different,” says Turnbull of Ford’s in-house motor design. The new unit has an edge in some respects, but we’re not talking night-and-day here. “They’re making connections to both the inside and the outside layers [of the windings],” says Turnbull. “There’s a total of four connections made with each of the three phases.” To what end? “That gives us something we call four parallel paths,” explains Turnbull. “That enables a little more current flow capability.” In comparison, the older motor had just two current paths to each winding.

There’s a more obvious change though, which becomes apparent when the camera pulls back. The Ford motor is quite a bit longer than the Borg Warner unit. This is because increasing the number of parallel paths tends to decrease the torque output of the motor (assuming no other limiting factors) —but there’s a way to make up for that. “In order to get the same torque, they had to increase the stack length for this,” says Turnbull. “That also again gives the motor great thermal capacity, and so that’s going to be an enabler for holding on to that torque a little longer to give them the quarter mile times they’re looking for.” Basically, with more “thermal mass,” the motor can run at high output for longer.

Ford’s winding layout could offer another side-benefit, too. “This winding bears very interesting similarity to the Hyundai winding, and Hyundai’s system is at 800 volts,” Turnbull explains. “All Hyundai has done is take the same winding and put in double the number of turns and go two parallel paths instead of four.” Basically, Turnbull reckons the new design could be easily reconfigured for an 800-volt setup instead of the current Mach-E’s 400-volt architecture. “This leaves Ford an option, an easy upgrade path, to get to 800 volts with this same winding configuration, and it’s just a slight difference in how they connect it up here.”

Turnbull also points out the welds that hold together the Borg Warner stator, which is assembled from a stack of laminated steel plates. It’s a typical technique to hold the stator together, but it does introduce some inefficiency due to its impact on eddy current losses. Basically, it’s ideal if the individual stator plates are isolated from each other, as this keeps eddy currents induced in the stator smaller. However, the weld effectively acts as a current path between the laminated stator plates and increases these losses. In contrast, Ford’s stator plates are simply bonded together adhesively and there is no big weld creating a current path for a large eddy current. It’s worth noting, though, that in both cases, there are bolts going through the stator stacks when fully assembled anyway.

To What End?

In any case, the new unit appears to outperform the old one quite handily. For the 2023 model year, the Mustang Mach-E GT put out 600 pound-feet of torque, or 634 pound-feet in the GT Performance Edition (GTPE) models. For 2024, the basic GT does the same 600 pound-feet, but it can be specced with the “Performance Upgrade” which boosts that to 700 pound-feet. Mighty!

While power remains the same at 480 hp, straight-line performance is improved with the new motor. In the GT models, zero-to-60 mph takes just 3.3 seconds in the top trim, down from 3.5 seconds in the former GTPE model. It’ll now do the quarter-mile in just 11.8 seconds, down from 12.4 seconds previously. That may very well be possible because the new motor is able to run flat-out for longer thanks to its greater thermal mass… or it could all be down to the added torque. Most likely, it’s a combination of both factors.

It’s worth noting that this wasn’t Ford just going off on a tangent on its own. Customers had long been questioning the Mach-E’s drag strip performance, particularly given curiously low trap speeds in some early runs by customers who shared their time slips on forums. One poster noted their top speed in the GTPE model was lower than some lesser trims, suggesting the motor was leaving performance on the table in the top end. Ford was well aware of this, too. “We heard, ‘we want better performance, and we definitely want a better quarter-mile time,'” Mach-E chief engineer Donna Dickson told Design News earlier this year. The new motor may quell some of those concerns given the 2024 model is dropping those faster drag-strip times.

Beyond that, there’s also the simple benefit of sharing parts across models, with Turnbull noting the motor is shared with the F-150 Lightning. There are, naturally, obvious cost savings to be had in scale by using the same motor across two models. Notably though, getting the truck motor to fit the Mach-E wasn’t easy. “It was pretty difficult, putting it in after we launched,” Dickson told Design News. It is a different shape and fitting it into our package with the subframe was difficult.”

It’s always interesting to see the changes that effect a car’s performance, particularly when they’re so physically evident. Munro Live gives us a great look under the hood, under the frunk… just about under every weird bit of these modern EVs. The truth remains that you can best understand a complicated system by pulling it down to its component parts.

Image credits: Munro Live via YouTube screenshot, Ford

My lease on my 2021 Select AWD with the standard battery just ended (all I could get in 2021 when cars were scarce due to semiconductor shortages) and upgraded to the premium AWD with extended battery and this motor on Friday. It’s like a whole different car. Very torquey and fun! I love the American tradition of shoving truck motors in cars.

“Turnbull is showing us a comparison between the stators of the old and new motors. That’s enough to illustrate the primary differences between the two.“

Ha.

I see what you did there.

You can tell it’s different… because of the way that it is. How neat is that?

I was commenting on the fact that in this AC electric motor the stator coil is the primary coil, so the primary difference is different primaries.

Well I thought it was funny.

I still think the mach-e shouldn’t be branded as a mustang.

It would make a better use of the maveric name than a truck or they could have made a new name for it instead of branding it mustang(a vehicle that for 60 years has been a front engine rear wheel drive muscle car, as far from giant electric 4 door suv as you can get).

You’re beating a dead horse here. Heh. Dead horse. Pun. Ha…

Parts sharing like this should ultimately bring down costs. Every bit helps.

Why they didn’t before is mind blowing, and is in no insignificant way, a contributor to why Ford is losing tens-of thousands of dollars on each EV it sells.

When GM says “Ultium” it really means this: a small set of common inhouse motors, modular configurations, and modular battery components. Ford should’ve been doing this from day one rather than using off the shelf, high-cost, EV components from a variety of suppliers.

My guess is that they had to lock down the design and get the supply chain going on the Mach E before the F150 motors were finalized and volume production was to the point where they could allot some to the Mach E. Also Ford probably ended up with excess F150 motors when they sold fewer F150s than they expected after ramping up production.

Or maybe the plan all along was to use outside parts until their own capacity was adequate. In any case giving up market share and waiting to enter with their own product would have been a bad idea.

All the auto companies but Tesla are loosing money on EVs until they catch up and the smart thing to do is make the money loosing period as short as possible, get market share, and get a reputation for building a desirable product. If they fail on any one of the three they are dead and they know it.

Fortunately the margins on gas pickups are ludicrously high so they have a fairly big pile of cash to burn.

Also Ford is still essentially a family business and as such they take a longer view than companies that answer to stockholders not named Ford.

The Toyoda, Porsche, Quandt and Tata, Chung (Hyundai), and Ford families are in it for the long haul, most of the other car companies stumble along from quarter to quarter trying to keep their stock holders happy.

Obviously the Agnelli family has lost control given the never ending Stellantis fiasco.

Misread this as the regular F150 engine and was hoping for a truly wild hybrid!

Side note, “mild to WILD” would be a great slogan for hybrid/ev performance parts!

The dipped ends of the stator windings are noteworthy. Instead of actually winding a continuous wire around the core, they’ve taken a bunch of U-shaped bars, slid them into the stator, welded them together at the ends, and dipped the ends in an insulating compound.

The welds could lower durability or introduce a little extra resistance at each interface, but traditional motor winding machines are big, slow, expensive, and rely on high precision. Doubly so for thick rectangular wire. I think this is a much smarter manufacturing method.

Totally beside the point, but do you think people (normal people, not engineers) will one day talk about their windings, stator stacks, and rotors the way they once spoke of forged pistons, radical cams, stroke and bore? Are electric motors even shade tree mechanic friendly? Just wondering how our associations with our cars will alter as electric becomes the standard.

Maybe, maybe not. When the ICE come on stage it was a totally new concept together with a car. While I’m sure it was “complicated” mechanical things being physical were probably easier to grasp than electrons flowing. An EV is clearly an evolution of the existing propulsion system rather than complete revolution, so I think what will happen is that once the tech matures (read: a decade or few) we may move on to modifying our EV cars much like OCers modify their PCs or game consoles. There’s a lot to discuss, compare and get excited about in that space, I don’t think EVs will be any different. Eventually.

I think it will be the same skill set as geeking out over subwoofer drivers, so I think the answer is yes.

Sadly, we will be talking CPUs and operating systems.

In many respects, when the EV market matures, there may be even more to do for “shade tree mechanics.” Jack it up and replace the motor. The entire motor. A few bolts, hopefully no high voltage shocks, and a new upgraded motor, just like that. Within hours, if that. The rest of these vehicles are pretty stock standard when it comes to axles, shocks, etc, although cooling is a thing that sets it apart (especially if you like i3…talking to you, DT…). And, if you’re a nerd, you can hack your car for even more performance, or range, if you’re a filthy hippie…

A 4 mega joule capacitor bank will be the new NO2 tank.

Mark my words, a nitromethane blower explosion will seem so quaint when things go wrong.

You mean N2O (nitrogen dioxide is a reddish-brown toxic gas), but yes, I agree with you otherwise.

Yeah, my bad.

I can see the types of people who change pistons and cams changing stator and rotors, and maybe winding their own stators if they’re really into it. You’ll have to mess with the control software to make things work right, but we already do that with ECUs. Don’t forget the thermal management though. It might be a bigger deal with EVs than with ICEVs.

Abso-fracking-lutely. I say this probably as one of the few people on this site more comfortable digging around in EVs than combustion, as well as someone who recently managed to

I always tell people it’s just a different skillset. We’re in an age roughly commensurate with the rise of ICE over steam and horses over a hundred years ago. You couldn’t go that far outside of a city or urbanized area because there wasn’t any developed petroleum infrastructure…. or possibly even roads. Only a handful of people could work on them, with everyone else learning on the fly or by getting things wrong. A lot of hand-wringing and fearmongering about new cars powered by EXPLOSIONS.

You can absolutely build up electric motors and change or upgrade inverters. In doing so, you probably will rip out whatever the OEM did, but how’s that different from doing an engine swap with an open source or aftermarket ECU? If any of you ever messed with R/C you know this is already done a ton. People used to hand-rewind and re-magnet DC brush motors, now they custom build the AC/brushless ones, share tuning files for the motor drivers, etc.

It’ll probably take decades for the “vernacular” knowledge around electric power to build up, just like it did for gas.

I’ll add that I have changed the output semiconductors on small e-bike inverters before to higher performance ones (you also have to fiddle with the driver circuit for those to match certain characteristics) to get more amps to the motor, then proceeded to lunch the gearbox the motor was attached to. I think this is the EV equivalent of too much boost.

I’ve spent a great deal of time on YouTube blowing up e-scooters in similar ways.

Nice! More go-fast bits for the Fake Mustang from one of the worst car companies on the planet!

I mean, worst “cars” maybe, but I imagine the sales data for the F-150 can’t all be wrong…

It’s not just the worst car-wise. Ever heard of Tucker? Ford made sure you didn’t. If you do some digging there are some hidden stories that put Ford in a new light.

Worst car companies? Stellantis is right there!

David…. You are going to let everyone know what a stator is but not ‘eddy current’? I do not believe that phrase is as well understood as you may have thought. Everyone correct me if I am wrong.

Also, ‘…electromagnet…’, not ‘…electromagnetic…’

Still, this is fun, and I always like to read your articles.

half way down the rabbit hole

can’t wait for the posts explaining subspace bubbles and warp field generators!

Heisenberg Compensator. If you get that joke, you are a TRUE NERD.

in for a bad day if your Heisenbergs stop compensating.

I’m not David. Granted, eddy currents and the like are something we should touch on in future.

Apologies.I am not remembering now why I thought that was a DT column. I should have read better.

What eddy currents are, why they happen, and why they hurt efficiency is probably a decent chunk of an article by itself rather than a couple sentences. While I personally rather like multi-layered digressions to describe engineering details, that might be pushing it even for this site.

I’ll be more interested when they make an electric Ford GT with this motor, with a curb weight of under 3,000 lbs.

Or at the very least, a normal Mustang CAR with this motor.

I don’t personally care about this car but I will say that the people who like them seem to really like them. I’m sure this is a welcome update for them…and the GT’s performance left a bit to be desired given the history behind that name.

We picked up a Premium AWD Extended Range under a lease for my wife to commute in, and it’s been fantastic so far. It’s plenty fast, continues to beat its quoted range, is a comfy drive, and means we haven’t gotten gas in our 4runner since the beginning of July (I only go in 2 days a week, and my commute is 6 miles).

I mean, my older 2022 Mach-E GT without the performance package is still 0.5sec quicker than a brand-new Mustang GT 5.0 WITH the performance package. I hardly think the performance is lacking.

I drove one for the first time a couple months ago and was very impressed. It was an EV driving event, so between 2 events, I drove about 8 EV’s. The Mach-E was one of my favorites, even though it was one of the older designs. I don’t in any way think the Mustang name should be on it, but it was a very nice driving SUV.

I want to like it (branding controversy and all), but I find it really ugly and too large for my use case. I hope some of the tech moves into more reasonably sized and less cartoonishly styled models soon.

Every review I’ve seen of the Mach E suggests it is a competent EV crossover. It’s just a shame Ford didn’t trust it to stand on its own merits and went with the dumb branding stunt.

I’m just glad there’s a refresh! With EVs where they are now in the market, choice is key.

Uniformity and reduced cost are more important than a marginal performance boost.

No doubt.